Table of Contents

ToggleIn the competitive world of product design and manufacturing, selecting the right materials and processes is paramount to success. When you need to combine a rigid substrate (like plastic or metal) with a soft, flexible component, overmolding is the go-to technique. But not all overmolding is created equal. While Thermoplastic Elastomers (TPEs) are common, Liquid Silicone Rubber (LSR) overmolding stands out as a superior solution for demanding applications. If you’re asking, “Why choose LSR overmolding?” you’ve come to the right place.

This in-depth guide will explore the seven key reasons why LSR overmolding is the preferred choice for industries where performance, safety, and durability are non-negotiable.

First, What is LSR Overmolding?

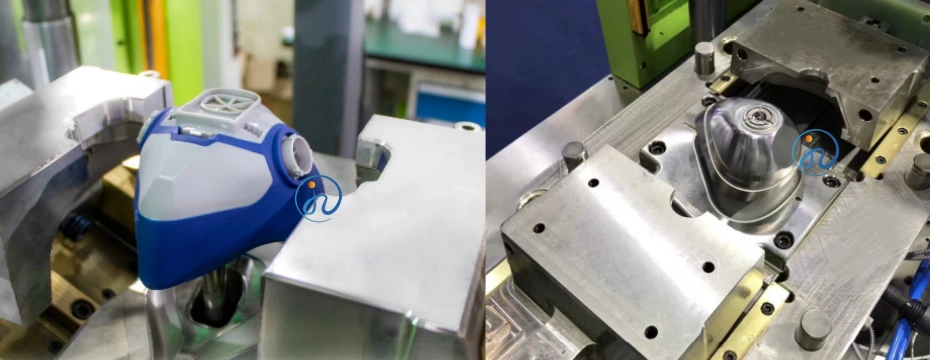

LSR overmolding is a high-precision, injection molding process where liquid silicone rubber is molded over a rigid substrate—known as the “first shot”—to create a single, seamless component. The substrate is typically a thermoplastic (like PC, PA, or Nylon) or metal part.

The process involves placing the substrate into a mold, then injecting liquid silicone, which cures and forms a permanent chemical and mechanical bond with the primary part. The result is a hybrid product that leverages the strengths of both materials: the structural integrity of the rigid component and the exceptional properties of silicone.

1. Unmatched Extreme Temperature Resistance

One of the most significant advantages of LSR overmolding is its ability to perform flawlessly in extreme temperatures where other materials fail.

- Performance Range: LSR maintains its flexibility and mechanical properties across a breathtakingly wide range, typically from -60°C to +200°C (-76°F to +392°F). Some specialized grades can even withstand temperatures up to 300°C (572°F) for short periods.

- Comparison: TPEs and TPUs soften, degrade, or become brittle outside their more limited ranges. This makes LSR overmolding indispensable for applications like:

- Automotive: Under-the-hood components, gaskets, and connectors.

- Consumer Appliances: Seals and gaskets for ovens, coffee makers, and irons.

- Aerospace and Defense: Parts exposed to high-altitude cold or engine heat.

2. Superior Biocompatibility and Safety

For products that contact skin, food, or medical fluids, safety is the highest priority. This is where LSR overmolding truly shines.

- Inert and Hypoallergenic: LSR is inherently inert, non-toxic, and does not support bacterial growth. It is naturally hypoallergenic, making it ideal for prolonged skin contact.

- Certifications: It easily meets stringent international certifications without requiring additives, including:

- USP Class VI (U.S. Pharmacopeia)

- FDA (Food and Drug Administration) compliance for food contact

- EU 10/2011 (European food contact regulations)

- ISO 10993 (Biological evaluation of medical devices)

- Applications: This makes LSR overmolding the gold standard for:

- Medical Devices: Respiratory masks, surgical instrument grips, drug delivery components.

- Baby Care: Bottle nipples, pacifiers, teethers.

- Food & Beverage: Seals for kitchenware, reusable food containers, and drink lids.

3. Exceptional Durability and Longevity

Products built with LSR overmolding are designed to last. The material’s inherent properties contribute to an exceptionally long service life.

- Tear and Abrasion Resistance: LSR offers excellent resistance to tearing and abrasion, even in thin-walled sections. This prevents failure in dynamic applications like buttons and seals that are constantly flexed.

- Permanent Flexibility: Unlike some TPEs that can stress-relax over time, LSR has a “memory” and will return to its original shape after repeated compression or stretching. This ensures a consistent seal and feel for the life of the product.

4. High-Precision and Complex Geometries

The liquid nature of LSR before curing allows it to fill incredibly intricate and delicate mold features that are challenging for thermoplastic materials.

- Thin Walls and Micro-Features: LSR overmolding can produce precise seals, membranes, and tactile features with wall thicknesses as low as 0.2 mm. This is crucial for miniaturized electronics and advanced medical devices.

- Consistency: The automated, closed-loop injection systems used in LSR manufacturing ensure exceptional part-to-part consistency, reducing waste and guaranteeing quality.

5. Excellent Chemical and Environmental Resistance

Products often encounter harsh chemicals, UV radiation, and ozone. LSR is naturally resistant to these environmental stressors.

- Chemical Resistance: It withstands exposure to many acids, alkalis, oxidizing agents, and solvents.

- Weathering Resistance: LSR is highly resistant to UV radiation, ozone, and moisture, preventing the cracking and degradation that can plague other elastomers. This is vital for:

- Outdoor Electronics: Seals for solar panel components, outdoor sensors.

- Automotive Exterior Parts: Weather seals that last the lifetime of the vehicle.

6. Enhanced Aesthetics and User Experience

Beyond performance, LSR overmolding significantly enhances the user interface and aesthetic appeal of a product.

- Tactile Feel: LSR can be formulated to provide a soft, smooth, or grippy texture that feels premium and comfortable in the hand. This improves ergonomics and user satisfaction.

- Branding Opportunities: It can be pigmented in a vast array of transparent, opaque, or custom-matched colors. This allows designers to create two-tone effects and integrate brand colors directly into the product’s structure.

7. Efficiency in High-Volume Production

While the initial tooling investment for LSR overmolding can be higher than for TPE, it becomes incredibly cost-effective at high volumes.

- Fast Cure Times: LSR cures rapidly under heat, leading to shorter cycle times.

- Automation-Friendly: The LSR process is highly automated, using metering, mixing, and dispensing equipment that feeds directly into the mold. This reduces labor costs and minimizes human error, ensuring consistent quality for millions of parts.

Conclusion: Is LSR Overmolding Right for Your Project?

So, why choose LSR overmolding? The answer is clear when your product demands the highest levels of performance, safety, and durability. If you are designing for the medical, automotive, consumer appliance, or any high-end industry where failure is not an option, LSR overmolding provides a reliable, high-quality solution that other materials cannot match.

While the process requires expertise in tool design and material science, the long-term benefits—from reduced failure rates to enhanced user satisfaction—make it a wise investment.