Table of Contents

ToggleWhen you embark on a project involving Liquid Silicone Rubber (LSR) injection molding, one of the most critical decisions you’ll face revolves around the LSR mold cavity. The question seems simple: “How many parts do I want per mold cycle?” However, the answer has profound and direct implications for your project’s budget, specifically the final unit price of each component.

Many manufacturers and product developers see the high initial cost of a multi-cavity mold and instinctively lean towards a single-cavity tool to save on upfront investment. While this can be a valid approach for prototypes or very low-volume production, it often leads to a higher long-term cost per part. Understanding the intricate relationship between lsr mold cavity count and unit price is not just a matter of accounting—it’s a fundamental principle of efficient manufacturing.

In this comprehensive guide, we will dissect the reasons why the number of cavities in your LSR mold is a primary driver of your part’s cost. We’ll explore the trade-offs between tooling investment and per-part price, the technical considerations unique to LSR, and how to determine the optimal cavity count for your specific production volume.

Understanding the Basics: What is an LSR Mold Cavity?

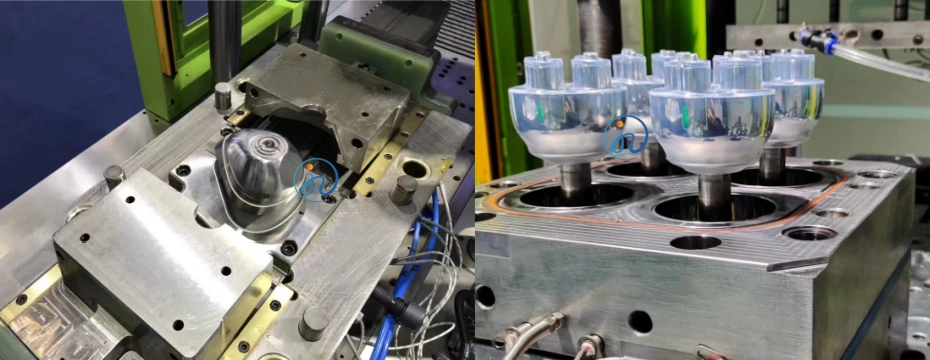

Before we dive into costs, let’s establish a clear definition. In injection molding, a cavity is the hollow space within a mold where the liquid silicone rubber is injected, forming the shape of the final part. A mold can have a single cavity or multiple cavities.

- Single-Cavity Mold: Produces one part per injection cycle.

- Multi-Cavity Mold: Produces two, four, eight, sixteen, or even more identical parts per cycle.

The primary goal of a multi-cavity mold is to increase production efficiency. By producing more parts in the same cycle time, you significantly reduce the manufacturing time and cost per part for large production runs.

The Direct Link: How Cavity Count Drives the Unit Price

The connection between lsr mold cavity count and unit price is a classic economic balance between fixed costs and variable costs. Here’s a breakdown of the direct impacts.

1. The Initial Tooling Investment: Amortization is Key

This is the most significant factor. The cost to design, machine, and finish an LSR mold increases with the number of cavities. A 4-cavity mold will not simply be double the price of a 2-cavity mold; the complexity often makes it more than double.

- Higher Manufacturing Cost: More cavities mean more complex machining. Each cavity must be precision-machined to be identical, requiring advanced CNC equipment and highly skilled labor. The mold base becomes larger and requires more material (hardened steel). Features like runners, cooling channels, and ejection systems also become exponentially more complex.

- Amortization of Cost: This is the crucial concept. The high initial cost of the mold (the “tooling cost”) is not a sunk cost. It is amortized—spread out—across every unit you produce.

- Amortized tooling cost per part: $5,000 / 100,000 = $0.05 per part

At first glance, the single-cavity seems better. But this is only part of the story. We must now add the cost of the injection molding process itself.

2. The Injection Molding Machine Cost: Cycle Time Efficiency

Running an injection molding machine costs money per hour (machine time, operator time, factory overhead). This is often called the “machine hour rate.”

- Single-Cavity Mold: To produce 100,000 parts, the machine must cycle 100,000 times.

- 4-Cavity Mold: To produce 100,000 parts, the machine only needs to cycle 25,000 times.

Although the cycle time for a 4-cavity mold might be slightly longer due to a larger shot size, it is nowhere near 4 times longer. Therefore, the total production time for 100,000 parts using a 4-cavity mold is drastically reduced.

Critical Considerations Specific to LSR Mold Cavity Design

LSR molding presents unique challenges that further influence the lsr mold cavity decision.

- Cold Runner Systems: Unlike thermoplastics, LSR uses cold runner systems to prevent premature curing. A multi-cavity mold requires a balanced cold runner system to ensure each cavity fills simultaneously and uniformly. Designing and manufacturing this balanced system adds to the mold’s complexity and cost but is essential for part quality and consistency across all cavities.

- Venting and Curing: LSR is viscous and requires excellent mold venting to avoid air traps. Each additional cavity increases the challenge of proper venting. Furthermore, the curing process must be consistent across all cavities, requiring precise temperature control. Any imbalance can lead to rejected parts, affecting the effective yield and cost.

- Part Complexity and Size: The physical size and complexity of your part dictate the feasible number of cavities. A large, complex medical component might only fit as a single cavity or 2-cavity mold, while a small, simple O-ring could be produced in a 32-cavity mold.

How to Choose the Right LSR Mold Cavity Count for Your Project

There is no one-size-fits-all answer. The optimal choice depends on your specific situation.

- Evaluate Your Production Volume:

- Low Volume (Prototypes, 1,000 – 10,000 parts): A single-cavity or 2-cavity mold is often more economical. The savings on initial tooling outweigh the higher per-part machine cost.

- Medium to High Volume (50,000+ parts): A multi-cavity mold (4, 8, 16) is almost always the most cost-effective choice. The amortized tooling cost becomes negligible, and the savings from reduced cycle times dominate.

- Consider Your Time to Market:

- A multi-cavity mold produces parts faster, helping you meet tight deadlines and get your product to market sooner.

- Factor in Future Demand:

- If you anticipate demand increasing, investing in a larger cavity mold now can save you from the expense of building a completely new mold later.

- Request a Detailed Quote:

- A reputable LSR molder will provide you with a detailed analysis, showing the tooling cost and piece price for different cavity options based on your expected volumes. This is the most reliable way to make a data-driven decision.

Conclusion: Balancing Investment with Efficiency

The decision regarding your lsr mold cavity count is a strategic one that directly dictates your unit price. It’s a fundamental trade-off:

- Lower upfront investment (single-cavity) leads to a higher long-term cost per part.

- Higher upfront investment (multi-cavity) leads to a significantly lower long-term cost per part.

For any project beyond very low-volume prototyping, opting for a multi-cavity LSR mold is the most financially sound decision. By understanding the principles of cost amortization and cycle time efficiency, you can engage in informed discussions with your molding partner and optimize your project for both cost-effectiveness and manufacturing success.

Ready to optimize your LSR molding project? Contact us today for a detailed quote that breaks down the cost impact of different cavity counts for your specific part.