Table of Contents

ToggleAs parents increasingly demand safer, more hygienic, and durable solutions for their infants, manufacturers of baby care products are turning to Liquid Silicone Rubber (LSR) overmolding as a game-changing technology. From pacifiers and baby bottle nipples to teething toys and feeding accessories, LSR overmolding offers unmatched benefits in performance, safety, and design.

This article explores the applications, advantages, and growing demand for LSR overmolding in baby care products, and why it is rapidly becoming the industry standard.

What Is LSR Overmolding?

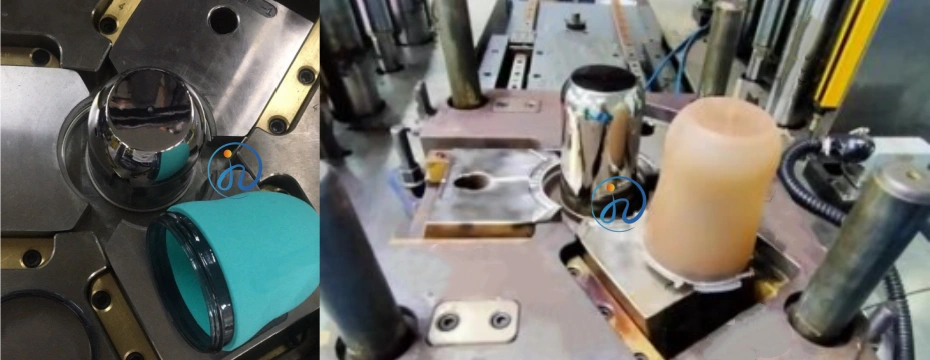

LSR (Liquid Silicone Rubber) overmolding is an advanced injection molding process where LSR is molded over another substrate—typically plastic (like polycarbonate, polypropylene, or nylon)—to create a dual-material component. The LSR material bonds chemically to the base material during the molding cycle, resulting in a single, integrated product.

In baby care products, this method is used to combine the soft, skin-safe qualities of LSR with the rigid structure provided by plastics, offering superior performance.

Why LSR Overmolding for Baby Care Products?

1. Exceptional Safety for Babies

LSR is inherently non-toxic, BPA-free, phthalate-free, and hypoallergenic. It is also compliant with international safety standards like FDA (U.S.), LFGB (Germany), and REACH (EU).

Overmolded baby products ensure there are no loose parts or adhesives, which minimizes choking hazards and allergic reactions—making them safe even for newborns.

2. Superior Hygiene and Sterilizability

Products made with LSR overmolding can withstand repeated sterilization through boiling, autoclaving, or UV disinfection. This is essential for items like:

- Baby bottle nipples

- Teething rings

- Pacifier shields

- Silicone feeding spoons

The non-porous nature of LSR also resists bacterial growth and odor absorption—key for maintaining hygiene in baby care items.

3. Soft-Touch Comfort with Structural Strength

LSR overmolding combines softness and flexibility with structural integrity. For example:

- A baby toothbrush can feature a rigid core for grip, overmolded with soft LSR bristles.

- A pacifier might have a sturdy handle for parents, overmolded with a soft nipple for babies.

This dual-characteristic makes products more ergonomic, comfortable, and functional.

Popular LSR Overmolded Baby Products

1. Pacifiers and Soothers

Overmolding allows pacifiers to be manufacturing as one-piece or multi-material components that are durable, safe, and gentle on gums.

2. Bottle Nipples and Caps

Soft LSR nipples overmolded onto hard plastic bottle caps ensure leak-free, seamless construction—ideal for feeding products.

3. Teething Toys

Soft, chew-safe LSR is often overmolded on plastic rings or handles, providing babies with soothing relief during teething.

4. Sippy Cups and Feeding Utensils

LSR grips and tips can be overmolded onto hard plastic handles, offering slip-resistance and added safety during feeding.

5. Breast Pump Components

Comfortable and hygienic flanges and shields are often made with LSR overmolding for a skin-friendly, durable solution.

Manufacturing Advantages of LSR Overmolding

1. Streamlined Production

Since LSR overmolding is done in a single mold cycle, it reduces assembly costs and eliminates the need for gluing or mechanical joining—minimizing risks of contamination or detachment.

2. High Volume and Precision

LSR injection molding is ideal for high-volume production with tight tolerances—perfect for scalable baby product manufacturing.

3. Design Flexibility

Manufacturers can create complex, ergonomic designs that combine textures, colors, and materials in a single part. Customization becomes easier, which is appealing for brands targeting niche baby care markets.

Compliance and Certifications

LSR overmolded baby products are compatible with global compliance standards:

- FDA 21 CFR 177.2600 (U.S. food contact safety)

- ISO 10993 (Biocompatibility)

- EN 14350 (EU safety standards for drinking equipment for children)

By using medical or food-grade LSR and certified molding processes, manufacturers can confidently bring safe, compliant products to global markets.

Sustainability and Eco-Friendliness

Unlike many thermoplastics, LSR is durable and long-lasting, reducing the frequency of product replacement. Additionally, since overmolding eliminates extra parts and adhesives, it reduces waste and enhances recyclability in the long term.

Some manufacturers are also exploring biobased LSR alternatives, aligning baby care products with eco-conscious consumer trends.

Key Considerations for OEMs and Brands

- Material Compatibility: Ensure substrate and LSR are chemically bondable.

- Tooling Investment: Custom molds are needed, but ROI is high for large production runs.

- Partner Selection: Choose experienced LSR injection molding suppliers who understand baby product safety standards and have cleanroom capabilities.

Future Trends in Baby Care Product Design with LSR Overmolding

- Smart baby products with overmolded sensors (e.g., temperature indicators in bottles)

- Personalized designs with multicolor LSR components

- One-piece hybrid designs for improved cleaning and sterilization

- Biocompatible wearables, such as soft baby thermometers or skin-safe patches

Conclusion: Why Choose LSR Overmolding for Baby Care Products?

In an industry where safety, durability, and comfort are paramount, LSR overmolding stands out as the ideal solution for manufacturing modern baby care products. Whether you’re producing pacifiers, teething rings, or feeding tools, LSR offers unmatched advantages in hygiene, softness, and performance.

For OEMs and baby care brands, adopting LSR overmolding isn’t just a trend—it’s a strategic move toward better product quality, customer satisfaction, and long-term brand success.