Silicone kitchenware, especially those crafted using liquid silicone rubber technology, showcases significant advantages across various kitchen applications with its high-temperature resistance, non-stick properties, and food-grade safety. Unlike plastic tools that may release harmful substances when exposed to high temperatures, or metal tools that can scratch utensils and are difficult to clean, silicone tools effectively avoid these issues. Compared to traditional silicone materials, LSR stands out even more in terms of temperature resistance and durability, making it an excellent choice for baking, cooking, and other kitchen tasks. Its flexibility ensures ease of use and maintains the integrity of food items. Moreover, the durability and corrosion resistance of LSR tools also guarantee their long-term reliability, positioning them as the ideal option for a wide range of kitchen uses.

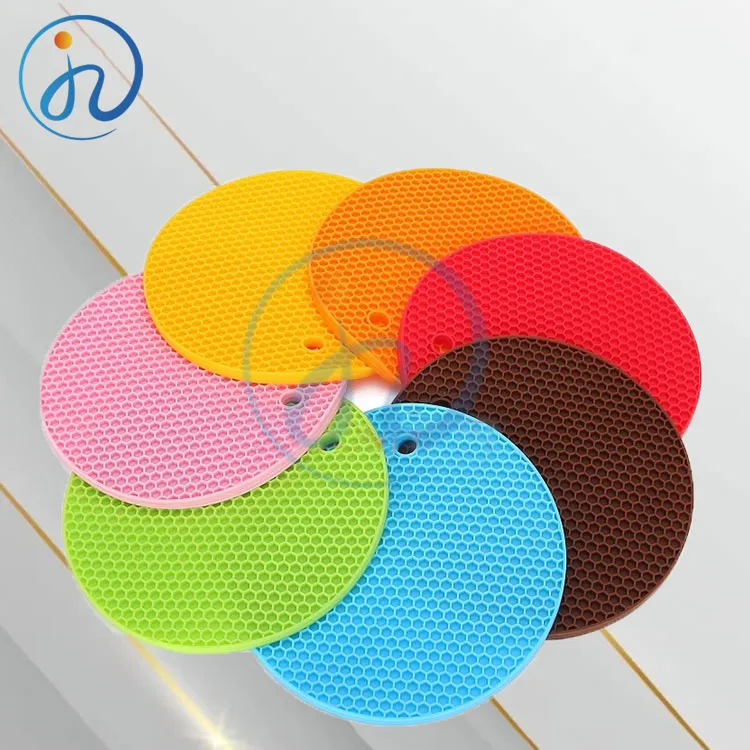

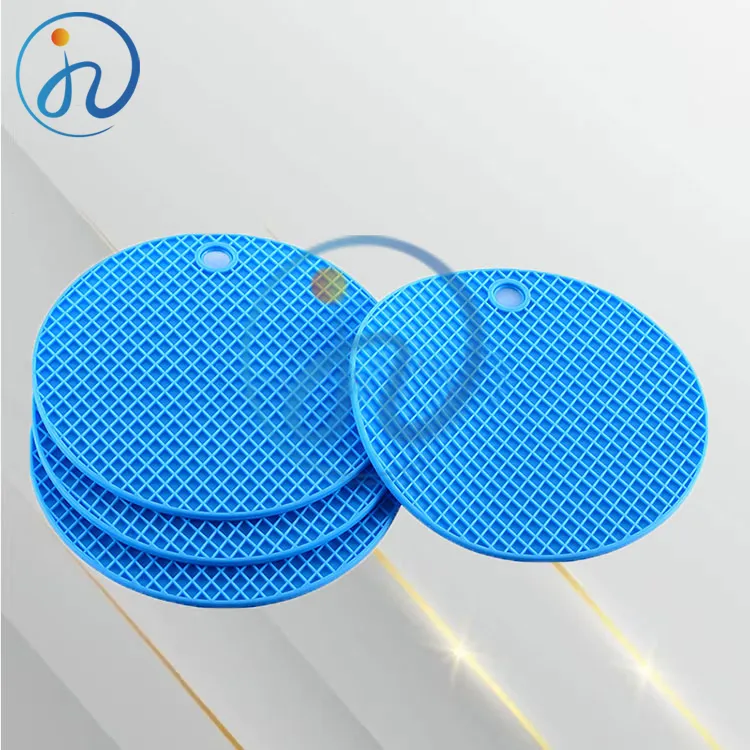

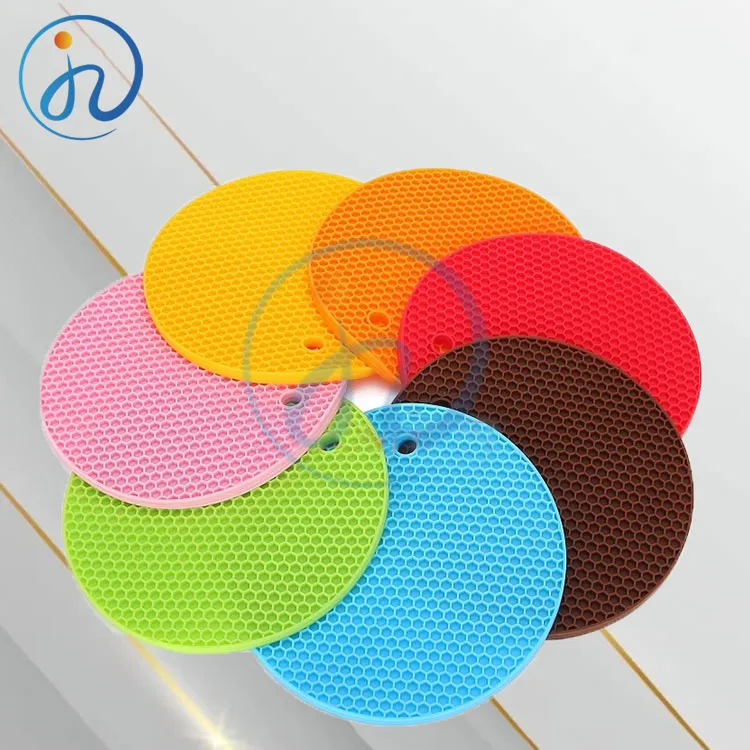

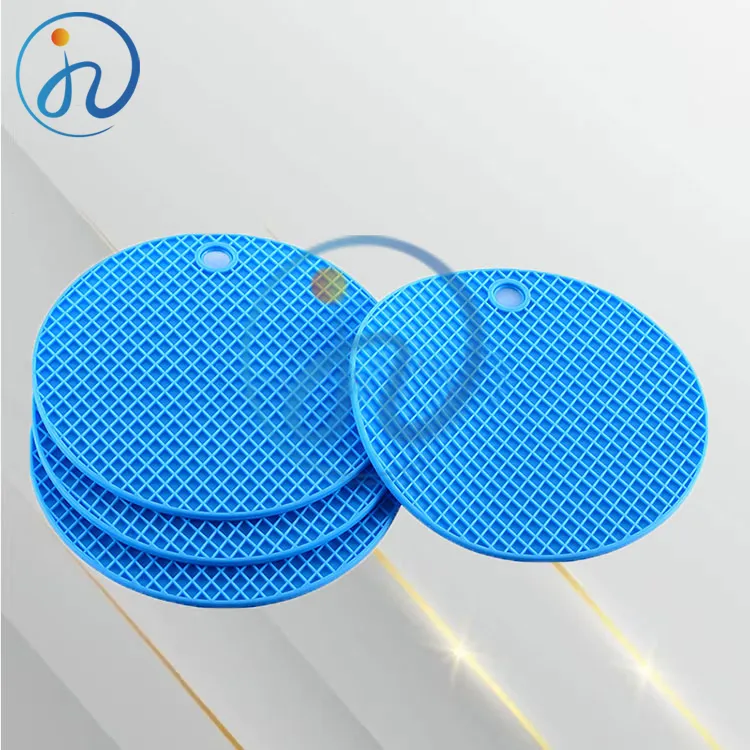

The range of applications for silicone kitchenware is extensive, encompassing everything from baking to cooking. In baking, silicone baking mats and molds are cherished by enthusiasts for their non-stick qualities and easy release benefits. In cooking, silicone spoons, spatulas, and mixing tools are widely appreciated for their durability and food-safe properties. Popular silicone kitchenware items include trays and food covers, which are not only safe and functional but also contribute to keeping the kitchen tidy, thereby improving the cooking experience. Moreover, silicone kitchenware is available in a multitude of colors and designs, offering the option to adorn your kitchen with items in black, white, red, and various other vibrant hues.

Silicone cooking tools, with their high-temperature resistance, non-stick properties, and food-grade safety, offer significant advantages over traditional metal or plastic cooking utensils. These tools do not release harmful substances at high temperatures and also avoid scratching cooking surfaces, greatly reducing the difficulty of cleaning.

Silicone baking tools, renowned for their heat resistance, non-stick qualities, and food-grade safety, provide substantial benefits over conventional metal or plastic baking accessories. Unlike their traditional counterparts, these silicone tools won’t leach harmful chemicals when exposed to high oven temperatures and prevent damage to delicate bakeware surfaces. This not only makes for an easier release of baked goods but also simplifies cleanup, enhancing the overall baking experience.

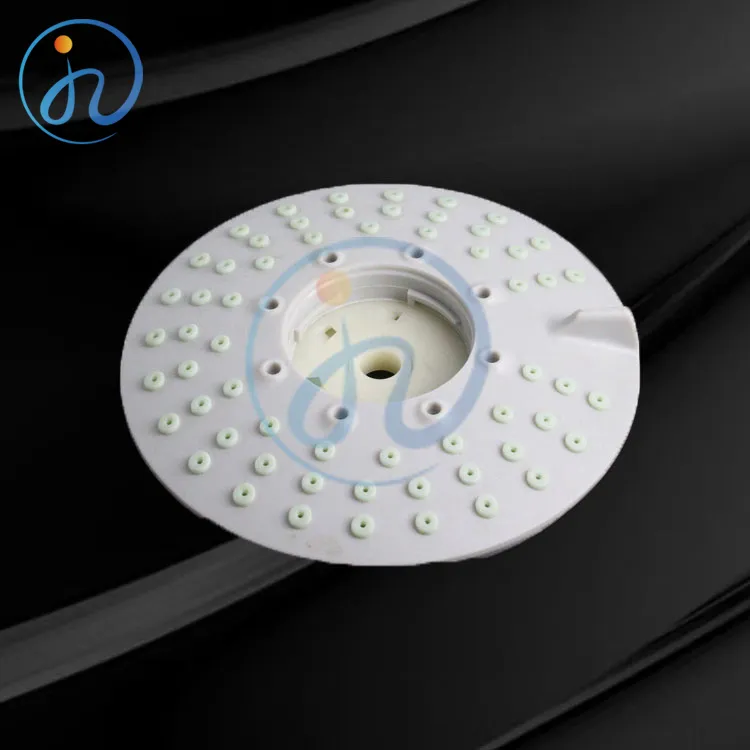

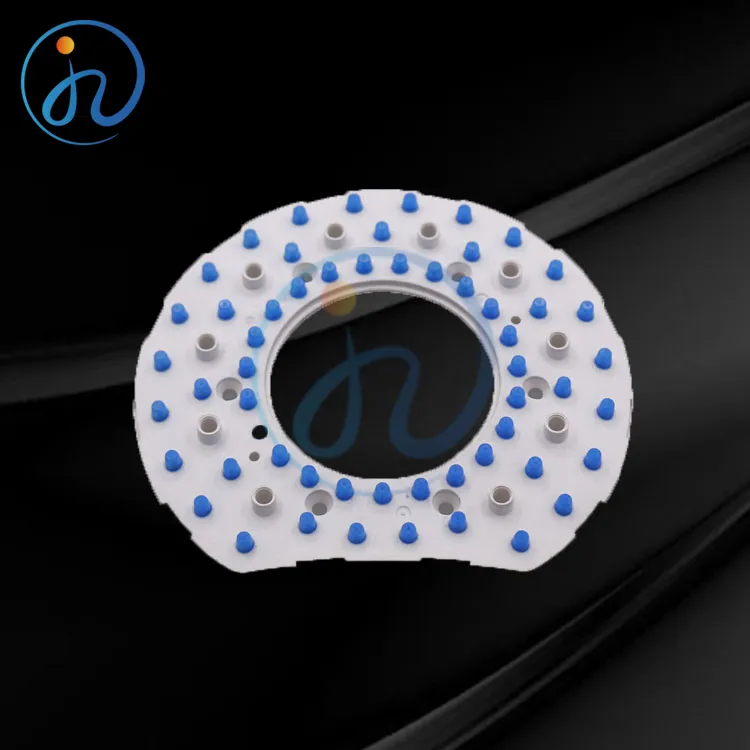

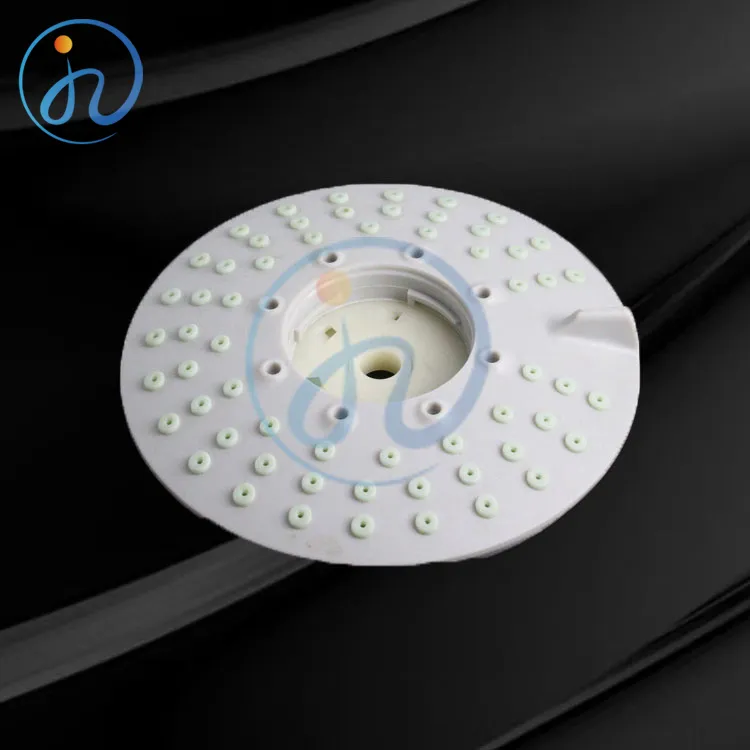

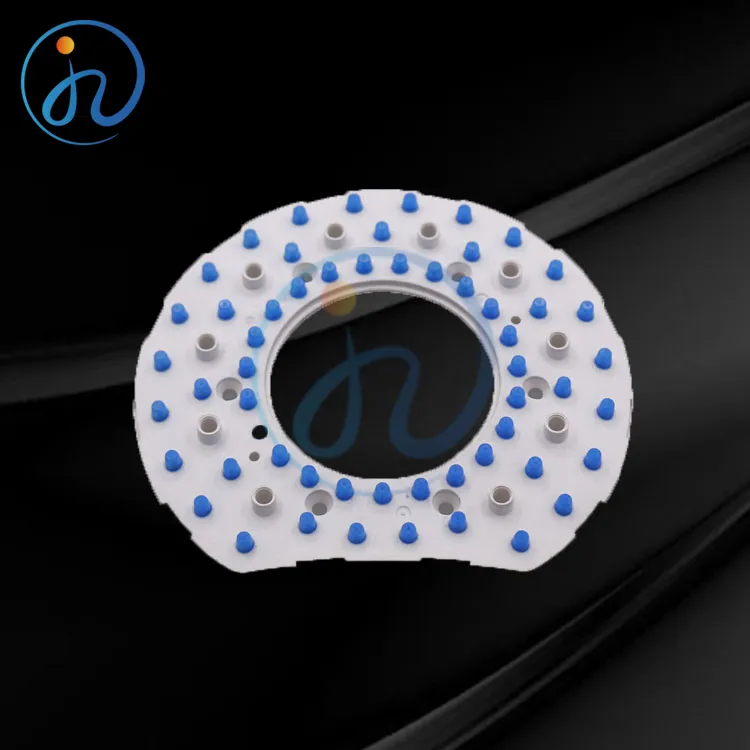

Silicone products, known for their environmental friendliness, high-temperature resistance, and safety, play an increasingly important role in modern life. Whether in cooking, food storage, or daily use, the versatility of silicone makes it an indispensable companion in households. For instance, collapsible bowls and bowls with lids facilitate the carrying and preservation of food, while suction bowls are particularly suitable for families with children, preventing food from being easily overturned. The sealing rings for pressure cookers and steamers ensure the safety and hygiene of the cooking process, and O-rings are widely used in various household and industrial equipment for their sealing capabilities. Additionally, trivets, food storage bags, and containers demonstrate the advantages of silicone in durability, ease of cleaning, and environmental sustainability, meeting the modern family’s pursuit of a healthy lifestyle.

Silicone kitchenware, especially those crafted using liquid silicone rubber (LSR) technology, showcases significant advantages across various kitchen applications with its high-temperature resistance, non-stick properties, and food-grade safety. Unlike plastic tools that may release harmful substances when exposed to high temperatures, or metal tools that can scratch utensils and are difficult to clean, silicone tools effectively avoid these issues. Compared to traditional silicone materials, LSR stands out even more in terms of temperature resistance and durability, making it an excellent choice for baking, cooking, and other kitchen tasks. Its flexibility ensures ease of use and maintains the integrity of food items. Moreover, the durability and corrosion resistance of LSR tools also guarantee their long-term reliability, positioning them as the ideal option for a wide range of kitchen uses.

Liquid Silicone Rubber (LSR), with its exceptional resilience and heat stability, stands out as the premier material for kitchenware components. Capable of enduring temperatures ranging from -50 degrees C to 250 degrees C, LSR confirms its utility in kitchen applications, especially when subjected to the rigors of ovens, stoves, and refrigerators.

Kitchen items like silicone spatulas, baking mats, and seal rings for pressure cookers are routinely exposed to variable temperatures and frequent contact with different food ingredients. LSR, celebrated for its unrivaled durability and flexibility, becomes the optimal choice for these kitchenware components. Its resistance to fading and discoloration from food dyes, combined with its immunity to damage from UV exposure and ambient kitchen ozone, solidifies its position as the preferred material for kitchen equipment that encounters daily wear and tear.

One notable trait of LSR is its non-stick characteristic, greatly simplifying the cooking and baking process. For kitchenware items such as baking molds, rolling pins, and various other silicone utensils, the non-adhesiveness offered by LSR is indispensable. This property not only facilitates easy food release and cleaning but also elevates the overall user experience and longevity of the kitchen tools.

For a comprehensive insight into LSR specifications and its aptness for your particular kitchenware application, we suggest perusing our technical data page or engaging with us directly. Our proficient team is primed to offer meticulous counsel and assistance, guaranteeing the triumph of your endeavors. Opt for LSR for your kitchenware components and witness a marked elevation in quality and functionality.

Silicone is a synthetic polymer made up of repeating units of siloxane (Si-O-Si) bonds. It is a versatile material with many desirable properties, including:

Liquid silicone rubber (LSR) is a type of silicone that is in a liquid state at room temperature. It is a two-part material that consists of a base polymer and a curing agent. When the two parts are mixed together, they react to form a cross-linked silicone network.

LSR has several advantages over other silicone materials, including:

Liquid silicone injection molding is a manufacturing process that uses liquid silicone rubber (LSR) to produce high-quality silicone parts. The process involves injecting LSR into a mold, where it is cured under heat and pressure. LSR Injection Molding offers several advantages over other silicone manufacturing processes, including:

Liquid silicone rubber is a type of silicone that is in a liquid state at room temperature. It is typically used in LSR Injection Molding to produce high-quality silicone parts. Regular silicone, on the other hand, is a solid at room temperature and can be used in various forms, such as sheets, tubes, and extrusions.

The main difference between liquid silicone rubber and regular silicone is their physical form. Liquid silicone rubber is a liquid, while regular silicone is a solid. This difference in physical form has several implications for the use of these materials.

Silicone kitchenware has several advantages over traditional kitchenware materials, including:

Yes, like all other products, silicone kitchenware will eventually wear out. However, with proper care and use, silicone kitchenware can last for several years. To extend the lifespan of your silicone kitchenware, please follow the care instructions provided by the manufacturer.

Silicone kitchenware utensils have become increasingly popular in recent years, replacing traditional plastic, wooden, and metal utensils. Many people have questions about whether silicone is safe and how it compares to other common materials.

Silicone is a polymer made up of silicon, oxygen, and carbon atoms. It has many advantages, including high-temperature resistance, low-temperature resistance, corrosion resistance, and wear resistance. It is also non-toxic and odorless, meeting food safety standards.

Plastic kitchen utensils are typically made of materials such as polyethylene and polypropylene. These materials can release harmful substances when heated at high temperatures, potentially posing a health risk.

Wooden kitchenware utensils are prone to bacteria growth and are not resistant to high temperatures or corrosion.

Metal kitchen utensils have good thermal conductivity, which can easily cause burns, and they may rust over time.

In comparison, silicone kitchenware utensils have the following advantages:

Therefore, silicone kitchenware utensils are non-toxic and a safer and more environmentally friendly choice than traditional materials such as plastic, wood, and metal.

Most silicone kitchenware is microwave safe. However, it is important to check the product's use instructions for specific temperature limitations. Do not microwave silicone kitchenware that contains oil or high-sugar foods.

Silicone baking molds can be used to make a variety of baked goods, including cakes, breads, cookies, pies, and mousses. Silicone is heat resistant and non-stick, making it easy to remove baked goods without damaging them.

When using silicone baking molds, please follow these precautions:

Silicone baking molds can be cleaned with warm water and detergent. They can also be placed in the dishwasher.

Silicone kitchenware can be used for a variety of cooking methods, including baking, frying, steaming, and boiling. Silicone is heat resistant and cold resistant, making it suitable for cooking a variety of ingredients.

When using silicone kitchenware, please follow these precautions:

Silicone kitchenware can be cleaned with warm water and detergent. They can also be placed in the dishwasher.

Our quality control procedures are consistent with ISO 9001:2015 standards, ensuring that our kitchenware silicone products uphold the rigorous requirements of the culinary industry. Our team is passionately committed to collaborating with clients, delivering technical guidance, and offering expert opinions to guarantee the success of ventures involving kitchenware silicone utensils and other related items.

We excel in the conceptualization, creation, and fabrication of superior kitchenware silicone items, addressing the distinct demands of the culinary sector. Our know-how and unwavering pursuit of excellence guarantee that our kitchenware silicone solutions, such as baking mats and spatulas, align with the efficiency and safety benchmarks set by our clientele.

We eagerly anticipate partnering with you on your upcoming kitchenware initiative, supplying the finest kitchenware silicone products tailored to your precise specifications, ensuring the comprehensive achievement of your project.

Should you have any questions or require further information about our services, do not hesitate to get in touch with us through our contact form. As a leading company in the LSR injection molding field, we greatly value communication and collaboration with our customers, and we are dedicated to providing you with high-quality service and support.

From mold design and development to custom manufacturing of LSR products, we offer a comprehensive one-stop service for you.