In the medical industry, the quality, precision, and safety of equipment and components are paramount. Liquid Silicone Rubber (LSR) is renowned for its excellent biocompatibility, heat resistance, and chemical resilience, making it an ideal choice for medical device manufacturing. The broad applications of LSR, including respiratory devices, fluid management systems, and syringe parts, provide reliable and efficient solutions for medical professionals.

JiaZe Silicone Tech is dedicated to providing a diverse range of Liquid Silicone Rubber (LSR) injection molding solutions for the medical industry. Our medical LSR product line encompasses a wide range of applications including but not limited to:

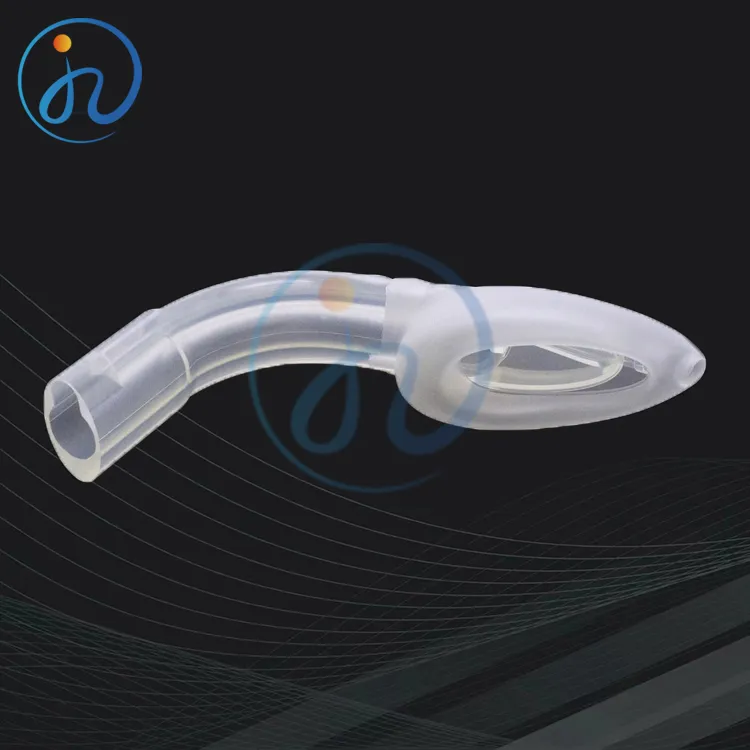

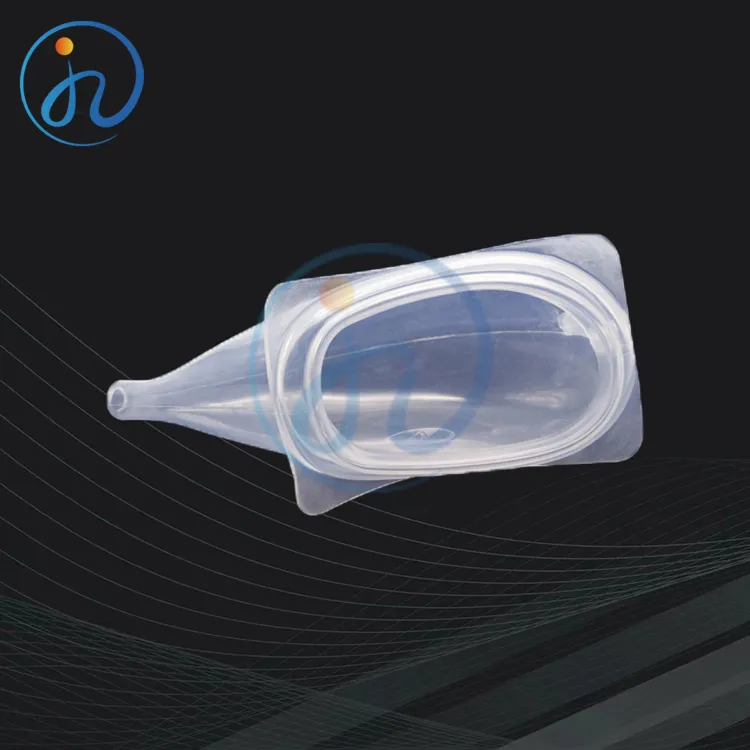

We offer Medical Silicone Overmolding Surgical Anesthesia Slipa, providing safe and reliable solutions for anesthesia applications during surgical procedures.

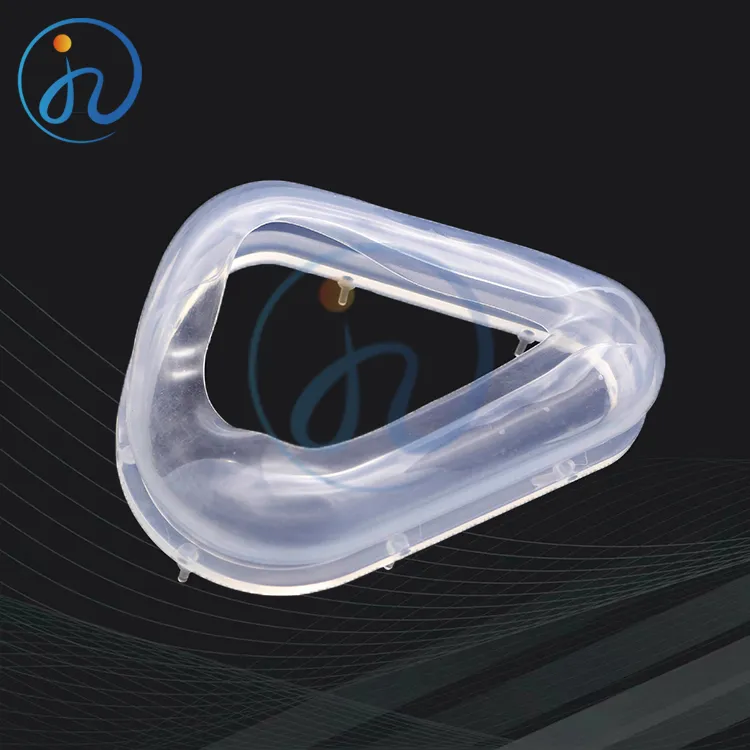

Our Silicone Plastic Overmolding Silicone Respirator Mask and Liquid Silicone Nasal Mask Components offer quality choices for respiratory therapy and protection.

Our Liquid Silicone Overmolding Sex Toys and Liquid Silicone Menstrual Cup offer safe and sanitary choices for personal care and women's health.

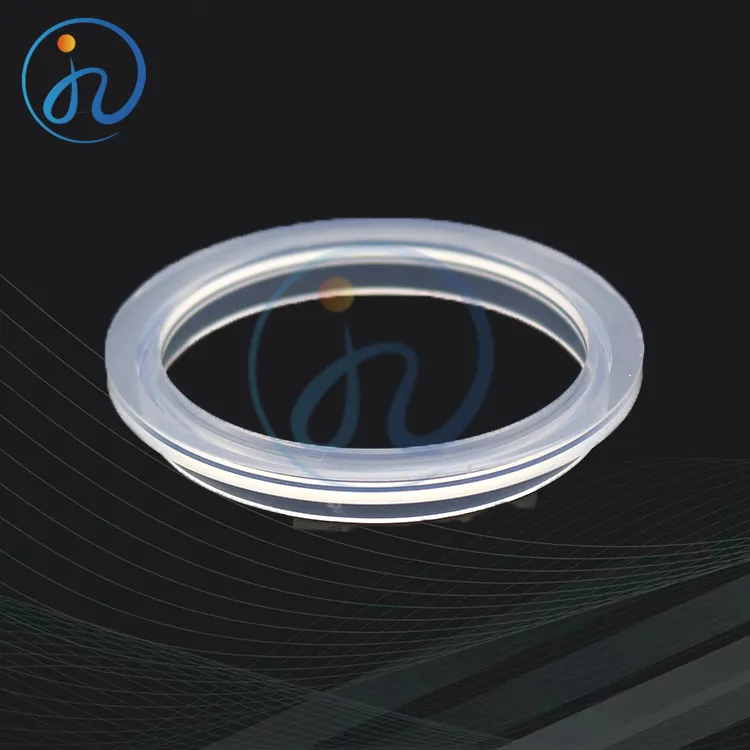

Our LSR Overmolding Silicone Parts and Seals provide high-quality sealing and connecting solutions to meet the stringent demands of medical devices.

Our Medical Silicone Metal Overmolding Scalpel and Silicone Metal Overmolding Orthodontic Tooth Brace provide precise, durable tools for surgical and dental treatments.

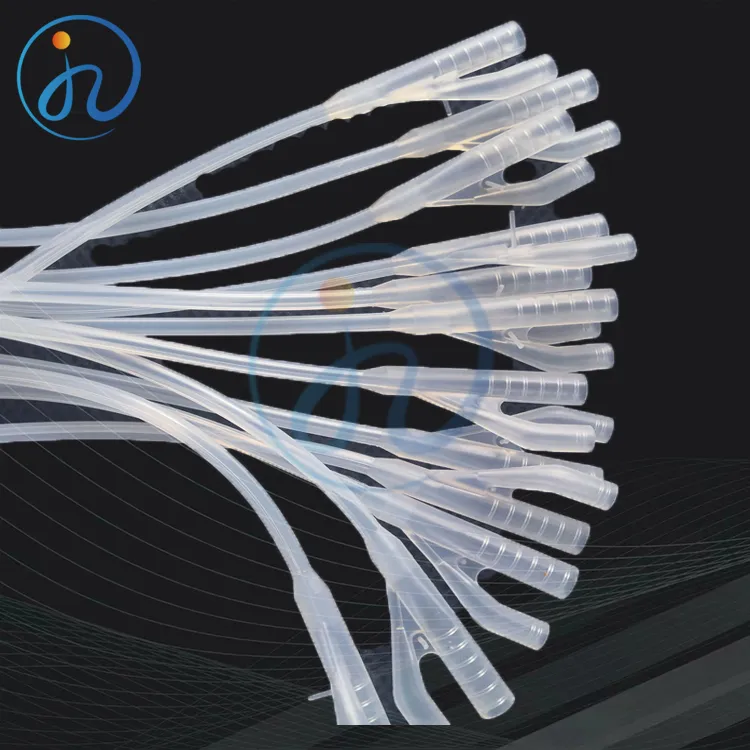

From Medical Silicone Urinary Catheter Parts to Medical Storage Tank Silicone Seal O Ring, our product range meets the diverse needs of the medical industry.

Medical-grade silicone is known for its superior quality and purity compared to food-grade, making it well suited for sensitive healthcare applications where safety is critical. It meets stringent standards to be classified as Class VI material. Medical silicone also has better resistance to extreme temperatures, beneficial for implants. Its reliability makes it a trusted choice in medicine.

High quality medical silicone products like sheets, tubing and custom parts are available from our company. Our experts can assist to select the right materials for your needs whether sealing, coatings or insulation. Please contact us to learn more about our medical-grade silicone offerings.

The versatility of medical silicone allows uses ranging from short-term disposable items like tubing to long-term implantables including pacemakers and prosthetics. Its unique properties have enabled applications such as catheters, valves, drug delivery devices and more.

Rigorous testing to meet ISO and FDA standards qualifies medical silicone as a safe material. Its non-toxicity, durability and versatility make it a trusted choice for medical uses. Medical silicone is popular for being skin-safe, durable, flexible and soft.

The key difference is the curing process. Typical silicone uses peroxide or high-temperature vulcanization. Medical grade undergoes additional certification to ensure it meets strict quality and safety standards for medical use and implantation.

Techniques like injection molding, compression molding and dip-molding allow shaping of medical silicone into high quality products. Injection molding forces liquid silicone into a heated chamber for even distribution. Compression molding uses heat and pressure. Dip-molding involves dipping an object to build up thickness.

The biocompatibility and durability of silicone make it a popular choice for many medical devices including:

Its properties are ideal for these and many other healthcare applications requiring biocompatible, durable and flexible silicone materials. The versatility of silicone makes it suitable for a wide range of medical devices and components.

The molecular structure of silicones gives stability, non-toxicity and insolubility in bodily fluids. Their hydrophobic surface prevents tissue reactions. These properties have enabled safe silicone use in biomedical applications and implants since the 1940s.

Key properties like strength, flexibility, and durability make silicone suitable for long-term implantable medical devices. Its hydrophobic nature suits contact with bodily fluids. Inertness reduces potential for immune reactions. These qualities contribute to silicone's effectiveness as a biomaterial.

Our quality control processes are in line with ISO 9001:2015 and ISO 13485:2016 certifications, ensuring our products and services meet the strict standards of the medical industry. Our team is dedicated to working closely with clients, providing technical support and professional advice to ensure the success of the project. Our strengths include but are not limited to:

Our advanced equipment ensures precision and efficiency in the production process.

We use only the highest quality medical-grade LSR materials to ensure the safety and performance of the products.

We continuously explore new technologies and methods to enhance our service quality and customer satisfaction.

Our engineers and technicians have extensive experience and expertise, providing valuable insights and support for your project.

Should you have any questions or require further information about our services, do not hesitate to get in touch with us through our contact form. As a leading company in the LSR injection molding field, we greatly value communication and collaboration with our customers, and we are dedicated to providing you with high-quality service and support.

From mold design and development to custom manufacturing of LSR products, we offer a comprehensive one-stop service for you.