One-stop LSR Product Customization Service

From mold design and development to custom manufacturing of LSR products, we offer a comprehensive one-stop service for you.

In manufacturing, Silicone Overmolding and insert molding are often mistaken for each other due to their similarities in the realm of injection molding. However, a closer examination reveals distinct differences, each with its unique advantages.

Silicone Overmolding involves molding silicone rubber over a substrate, enhancing protection, aesthetics, and functionality. This method ensures products withstand temperature variations and mechanical stresses, optimizing longevity. Insert molding, conversely, encases a preformed part (the insert) with molten material in a mold, ideal for integrated, cohesive structures and embedding components.

Both processes serve varied applications, from safeguarding electronics to enhancing tool grip. Understanding their unique attributes allows for the optimization of product design and functionality.

Silicone Overmolding, a remarkable facet of the modern manufacturing world, is revolutionizing product design and functionality. Harnessing the exceptional properties of Liquid Silicone Rubber (LSR), overmolding offers versatility, durability, and impeccable finishing touches to a plethora of products. At JiaZe Silicone Tech, we pride ourselves on spearheading innovative overmolding solutions, catering to a myriad of industries. Our expertise in LSR overmolding encapsulates various applications, each tailored to address distinct challenges and fulfill specific needs.

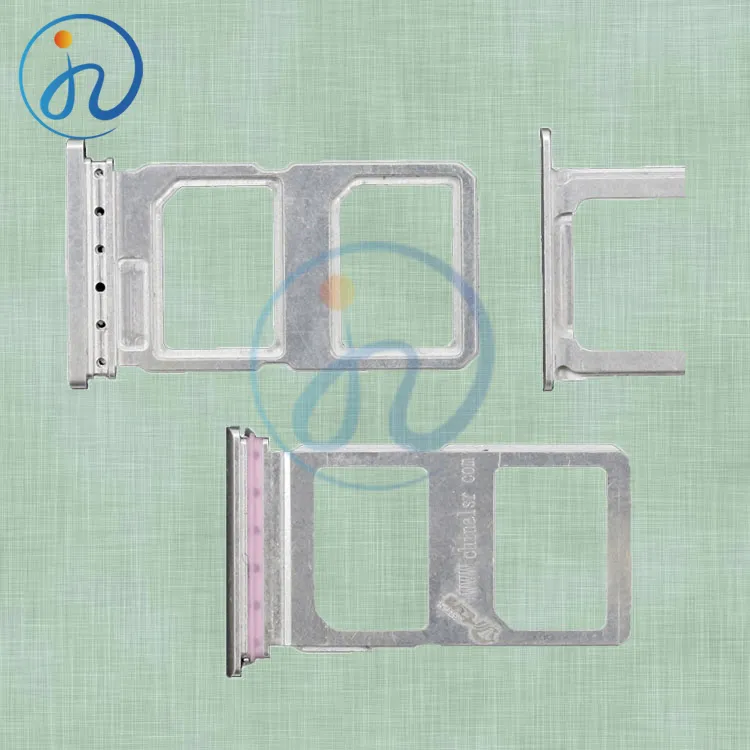

Silicone overmolding plays an integral role in protecting sensitive electronic components. Its insulating properties, combined with resistance to environmental factors like moisture and dust, ensure that electronic gadgets and circuitry remain shielded, enhancing longevity and performance.

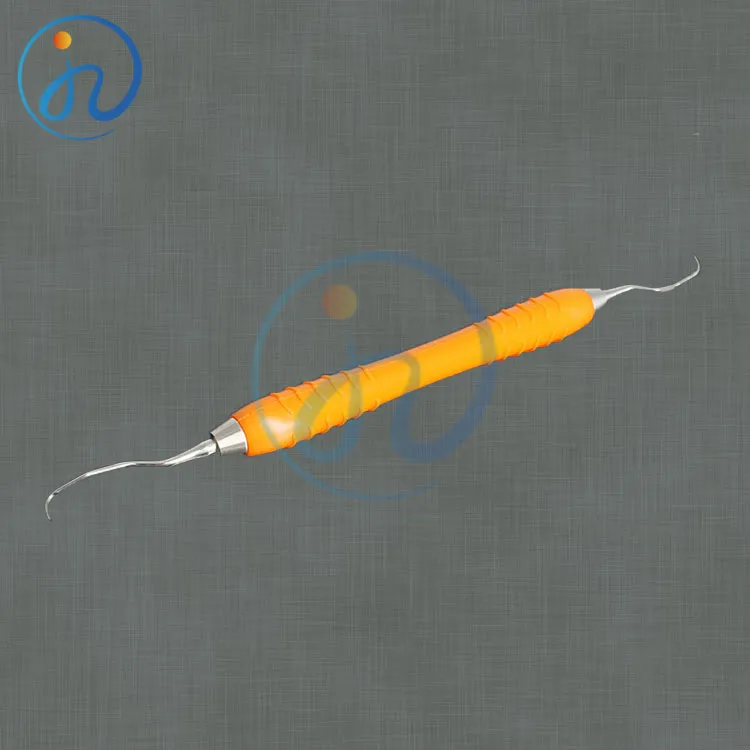

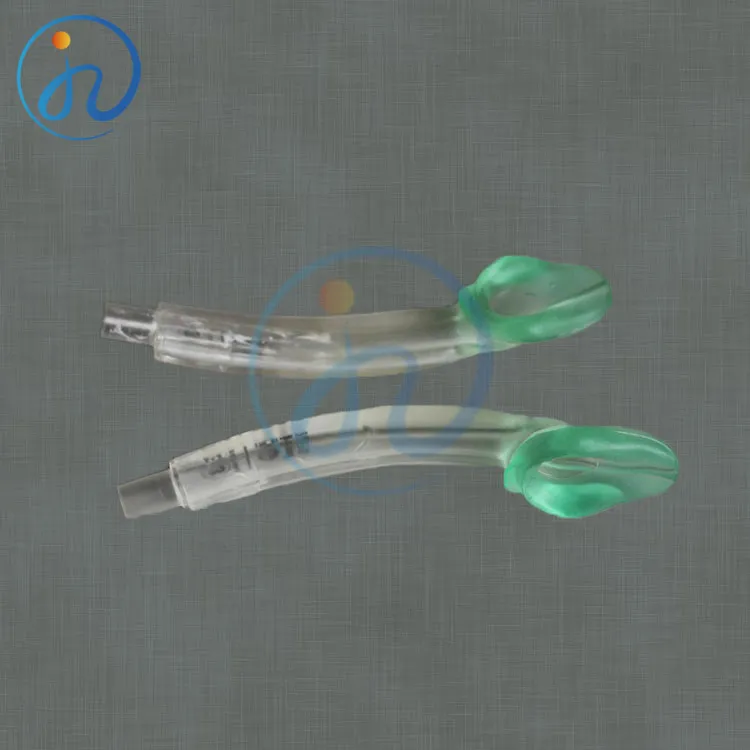

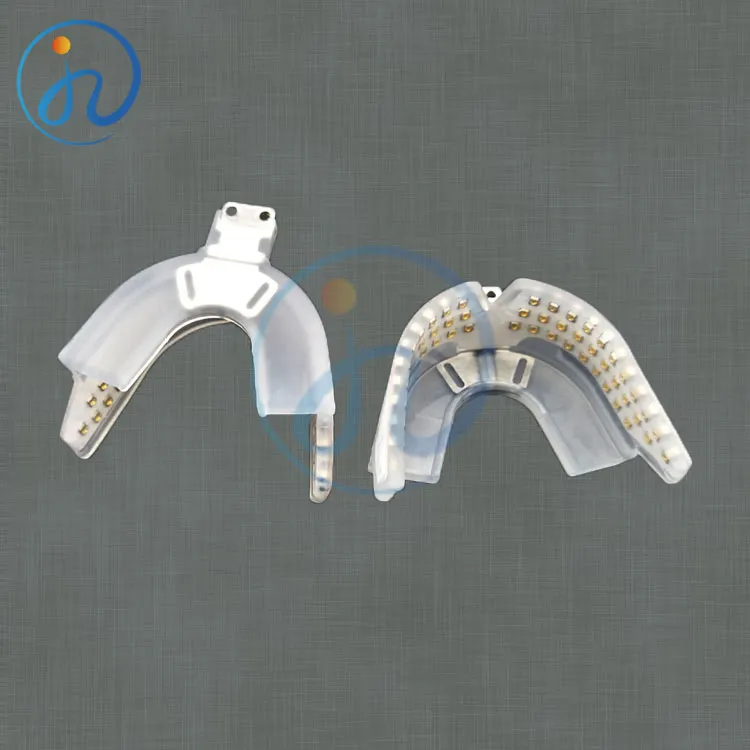

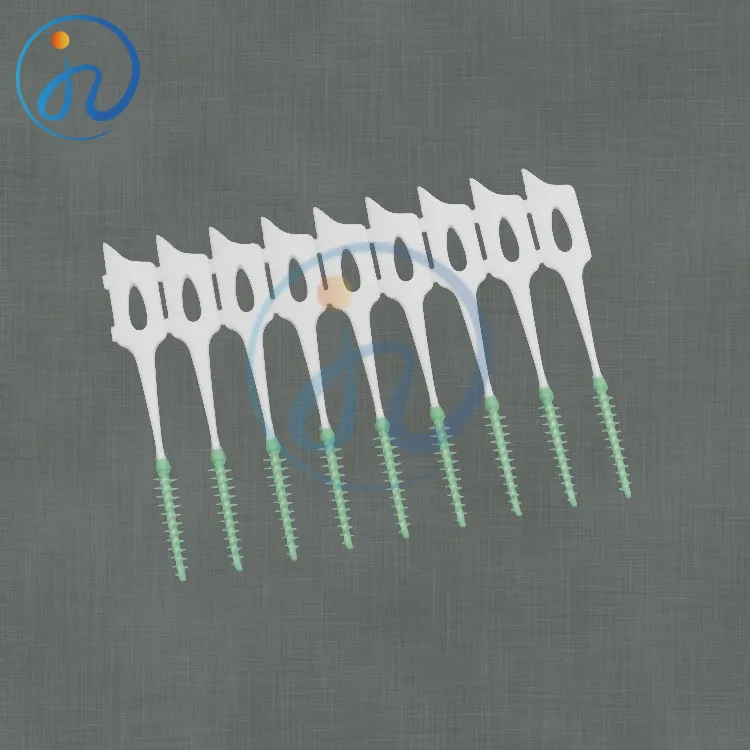

In the medical realm, silicone overmolding offers biocompatible solutions. From surgical tools to wearable monitors, overmolded components are resilient against sterilization processes and are hypoallergenic, ensuring patient safety and device durability.

The use of silicone overmolding in crafting tool handles guarantees a comfortable and non-slip grip. It's not just about aesthetics; overmolded handles enhance user safety, reduce fatigue, and improve overall efficiency in tasks.

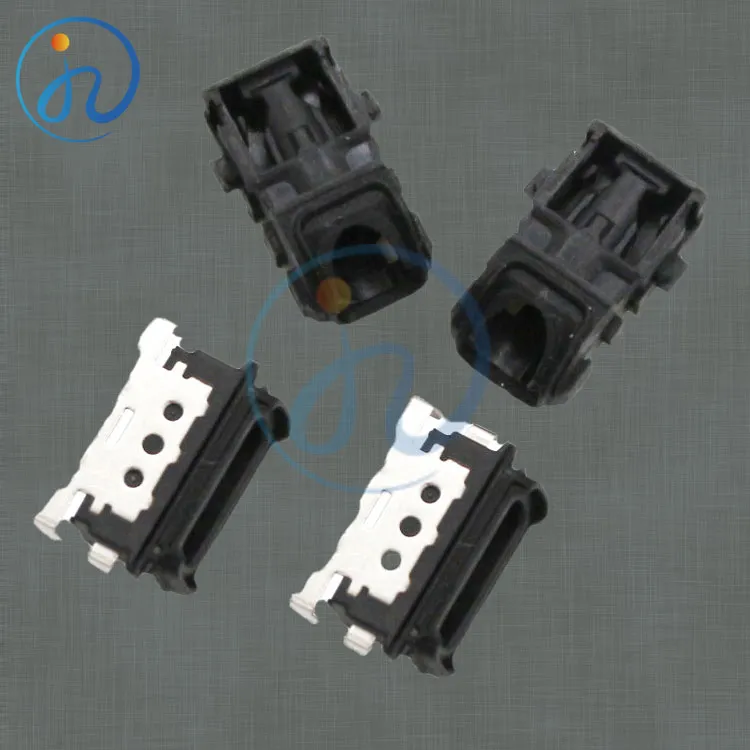

n the automotive sector, silicone overmolding provides components with enhanced durability, heat resistance, and vibration dampening. It's particularly useful for parts located in harsh environments within a vehicle, ensuring prolonged service life.

For everyday home appliances, from coffee makers to washing machines, silicone overmolding ensures user-friendly interfaces, aesthetic appeal, and improved component longevity. The resistance to heat and moisture makes overmolded parts a favorite in this sector.

Wearable gadgets, be it fitness trackers or smartwatches, benefit immensely from silicone overmolding. The resulting product is lightweight, skin-friendly, and resistant to factors like sweat and water, optimizing user experience.

Liquid Silicone Rubber (LSR) overmolding stands out in the manufacturing arena, renowned for its adaptability and efficiency. A striking feature of LSR overmolded components is the ability to seamlessly integrate with non-plastic bases, like metals. Interestingly, overmolding remains a unique method that permits the fusion of diverse materials, excluding traditional thermoplastics, within the injection molding domain.

Manufacturers spanning various sectors leverage LSR/plastic injection molding, from crafting ergonomic handles to engineering intricate electronic modules. Here's a closer look at why LSR overmolding might be the optimal solution for your next venture:

Dual Material Benefits: LSR overmolded products inherit the advantages and properties of both constituents, offering a blend of rigidity and flexibility, coupled with sealing and insulation features.

Integration of Diverse Substrates: Overmolding stands unparalleled in its ability to bring together materials beyond the usual thermoplastic and LSR spectrum, expanding the horizons of injection molding.

Economic & Temporal Efficiency: Molding silicone directly onto substrates like metal or other plastics eradicates the requirement for subsequent assembly steps. This direct approach translates to tangible cost and time savings.

Enhanced Design Possibilities: Introducing silicone rubber into the mix results in parts boasting superior waterproofing, airtightness, and augmented resilience against mechanical disturbances.

Stringent Quality Assurance: The precision inherent to the LSR molding method ensures the production of top-tier, firmly-attached components, underlining the quality commitment.

In essence, LSR overmolding is a testament to the evolution of manufacturing, reflecting the industry's move towards versatility, efficiency, and quality. Engaging with this technology ensures not just a product, but a promise of excellence.

Both overmolding and 2-shot molding are advanced techniques that fuse two distinct materials into a unified, multi-material component.

In the overmolding procedure, Liquid Silicone Rubber (LSR) is skillfully layered over a pre-positioned metal or plastic base. This approach allows for a vast range of material combinations, enhancing the resultant component's attributes and resilience.

On the other hand, the 2-shot molding technique introduces both materials in a synchronized manner using the same equipment. Through meticulous cavity-to-cavity alignment, this method guarantees impeccable bonding and precise material placement.

Our commitment to quality is uncompromising. With quality control processes that align with ISO 9001:2015 and IATF 16949:2016 certifications, we guarantee our LSR overmolding products and services uphold the most rigorous standards in the industry. Our team, driven by a passion for excellence, partners closely with clients, extending technical support and expert advice to ensure successful outcomes in all overmolding projects.

Our specialty lies in the meticulous design, development, and fabrication of high-caliber LSR overmolded components. Catering to diverse industry needs, we infuse our vast knowledge and dedication into every project. Whether it's a complex overmolded electronic assembly or an ergonomic tool grip, our solutions are tailored to meet and exceed the performance and safety benchmarks set by our clients.

As you embark on your next overmolding project, consider us as your trusted partner. Together, we can craft top-tier LSR overmolded products that align seamlessly with your specifications, ensuring the unparalleled success of your venture.

Should you have any questions or require further information about our services, do not hesitate to get in touch with us through our contact form. As a leading company in the LSR injection molding field, we greatly value communication and collaboration with our customers, and we are dedicated to providing you with high-quality service and support.

From mold design and development to custom manufacturing of LSR products, we offer a comprehensive one-stop service for you.