Table of Contents

ToggleThe role of an LSR injection manufacturer is critical in today’s advanced technological landscape. Liquid Silicone Rubber (LSR) is a high-purity material renowned for its exceptional thermal stability, biocompatibility, flexibility, and durability. From life-saving medical devices and baby care products to rugged automotive seals and soft-touch consumer electronics, the applications are vast and demanding.

Becoming a successful LSR injection manufacturer requires more than just owning a molding machine. It demands a deep understanding of material science, a mastery of specialized processes, and an unwavering commitment to quality. This comprehensive guide will walk you through the essential pillars that separate a competent manufacturer from an industry leader.

Understanding the Unique Nature of LSR Material

Before diving into the process, it’s crucial to understand what sets LSR apart from thermoplastics. This foundation is key to making informed decisions at every stage of manufacturing.

- Two-Part Chemistry: LSR is supplied as a two-part system (Part A and Part B) that, when mixed in a precise 1:1 ratio, initiates a platinum-catalyzed addition cure reaction. Unlike thermoplastics, there are by-products, making it a very clean process.

- Low Viscosity: In its uncured state, LSR has a very low viscosity, similar to pancake batter. This allows it to fill incredibly intricate and delicate mold features easily but also necessitates careful control to prevent flashing.

- Thermal Cure: LSR cures with heat. The material is typically injected cold into a heated mold (typically between 180°C – 220°C / 356°F – 428°F), where it rapidly vulcanizes.

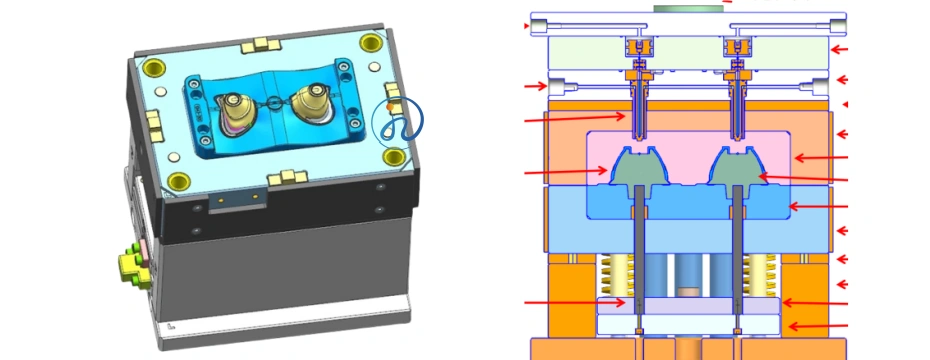

The Core Process: Advanced LSR Injection Molding Equipment

A proficient LSR injection manufacturer invests in specialized equipment designed specifically for LSR’s unique behavior.

1. Specialized LSR Injection Molding Machines:

- Cold Runner System: The material barrel and screw are cooled (often with chilled water) to prevent premature curing in the barrel.

- Positive Displacement Pump: Instead of a standard rotating screw for injection, LSR machines often use a precision metering pump to deliver the exact volume of material into the mold. This provides superior shot control for the low-viscosity liquid.

- Static Mixer: Located just before the nozzle, this critical component thoroughly mixes the two-part LSR (A & B) immediately before it enters the mold, ensuring a consistent and complete cure.

2. Mold Design and Engineering Excellence:

The mold is the heart of the operation. For an LSR injection manufacturer, mold design is arguably the most important factor for success.

- Cold Runner vs. Hot Runner Systems: While cold runners are common, hot runner systems (which keep the material at a precisely controlled, elevated temperature just below the curing point) are advanced solutions that eliminate material waste and can improve cycle times.

- Venting: Due to the low viscosity of LSR, proper venting is non-negotiable to allow air to escape the mold cavity. Insufficient venting causes trapped air, leading to burns, short shots, and defective parts.

- Gating: Gate design is critical. Diaphragm, edge, and submarine gates are common. The gate must be designed to allow easy fill and a clean break-off, minimizing post-processing.

- Cooling Channels: Efficient cooling is vital for achieving fast cycle times. Complex conformal cooling channels that follow the contours of the mold cavity can be highly beneficial.

- Materials: Molds are typically made from high-grade, corrosion-resistant stainless steel (e.g., 420 Stainless Steel) to withstand the abrasive nature of some LSR compounds and ensure a long, productive mold life with a high-quality surface finish.

Pillars of a World-Class LSR Injection Manufacturer

Beyond the machinery, several operational and philosophical pillars define a top-tier manufacturer.

1. Uncompromising Quality Control and Consistency

- Statistical Process Control (SPC): Monitoring key process parameters (injection speed, pressure, temperatures, cure time) in real-time to ensure they remain within strict control limits.

- Traceability: Implementing robust systems to trace raw material lots through to finished goods, which is absolutely critical for regulated industries like medical and automotive.

- Comprehensive Testing: Performing regular tests on finished parts, including:

- Dimensional checks (using CMMs and optical comparators)

- Mechanical properties (tear strength, elongation, durometer)

- Biocompatibility testing (as required)

- Chemical resistance and heat aging tests

2. Expertise in Secondary Operations

While LSR is often a “finish-in-mold” material, some applications require secondary operations. A skilled LSR injection manufacturer offers these services in-house for better control and efficiency.

- Deflashing/Cryogenic Deflashing: The most common secondary operation. Using a tumbling process, often at cryogenic temperatures, to remove the thin layer of flash (excess material) from the part.

- Post-Curing: Some LSRs benefit from a post-cure cycle in an oven to enhance certain physical properties, such as compression set.

- Bonding/Overmolding: A key expertise is bonding LSR to other substrates like thermoplastics (e.g., PP, PC, Nylon) or metals. This requires deep knowledge of material compatibility, surface treatments, and specialized molding techniques like two-shot molding.

3. Navigating Industry-Specific Standards and Certifications

Credibility is building on certifications. A reputable LSR injection manufacturer will hold and adhere to relevant international standards.

- ISO 13485:2016: The gold standard for Quality Management Systems in the medical device industry. Non-negotiable for medical manufacturing.

- IATF 16949: The equivalent standard for the automotive industry, demonstrating capability in its rigorous quality and process control standards.

- ISO 9001: The baseline for quality management systems.

- FDA Compliance & USP Class VI: Essential for products contacting food or drugs in the U.S. market.

- Cleanroom Molding: For medical, pharmaceutical, and optical applications, manufacturing in a certified cleanroom (e.g., ISO Class 7 or 8) is essential to prevent particulate contamination.

4. Fostering a Collaborative Partnership with Clients

The best manufacturers don’t just take orders; they become partners.

- Design for Manufacturability (DFM): Engaging with clients early in the design phase to optimize part geometry for the LSR process, suggesting draft angles, radii, and wall thicknesses that will ensure manufacturability, quality, and cost-effectiveness.

- Material Selection Guidance: Advising clients on the optimal LSR grade based on the application’s requirements for hardness, color, fluid resistance, and regulatory compliance.

- Transparent Communication: Maintaining clear and proactive communication throughout the project lifecycle, from prototyping to full-scale production.

The Roadmap to Success: A Summary

Becoming a leading LSR injection manufacturer is a journey of continuous improvement and specialization. It involves:

- Investing in the Right Technology: From specialized LSR machines to precision molds.

- Cultivating Deep Expertise: Understanding the material’s chemistry and behavior intimately.

- Implementing Rigorous Systems: Building a quality management system rooted in data and traceability.

- Pursuing Relevant Certifications: Building trust and opening doors to high-value industries.

- Adopting a Partnership Mindset: Working collaboratively with clients to solve complex challenges.

By mastering these areas, an LSR injection manufacturer can position itself as a reliable, innovative, and high-quality partner, capable of meeting the stringent demands of the world’s most challenging and rewarding industries. The future of LSR is bright, and it belongs to those who are dedicating to the craft of manufacturing excellence.