Table of Contents

ToggleIf you’ve recently requested quotes for a Liquid Silicone Rubber (LSR) mold, you’ve likely encountered a puzzling scenario: the prices from different factories can vary dramatically. One factory might quote $15,000, another $30,000, and a third $50,000 for what seems to be the same part.

This wide disparity in LSR mold quotation isn’t a sign of a chaotic market; it’s a direct reflection of the vast differences in quality, capability, and long-term value offered by mold manufacturers. Choosing based solely on the lowest price is one of the costliest mistakes a business can make.

This in-depth guide will deconstruct the core factors that influence an LSR mold quotation, empowering you to understand what you’re truly paying for and how to select the right partner for your project.

1. The Foundation: Mold Steel Quality & Grade

The steel forms the very foundation of your mold. Its quality dictates the tool’s lifespan, maintenance frequency, and the consistency of your final parts.

- Corrosion Resistance is King: LSR contains additives (like platinum catalysts) that can be highly corrosive. Standard tool steels will rust and pit quickly, leading to defective parts and constant maintenance. High-quality factories exclusively use Premium Corrosion-Resistant Steel (e.g., Stavax ESR, Mirrax ESR, or equivalent grades). This steel is an investment that prevents astronomical downtime costs later.

- Hardness and Purity: Top-tier steels offer superior hardness and purity, achieved through processes like Electro-Slag Remelting (ESR). This results in a uniform structure that can withstand the thermal cycling of LSR injection molding without developing micro-cracks. Lower-cost factories may use inferior, less pure steels that are prone to premature failure.

The Quotation Impact: The cost difference between premium and standard steel can be thousands of dollars, but it’s non-negotiable for a durable, high-volume LSR mold.

2. The Heart: Hot Runner System Selection

The hot runner is the heart of any LSR mold, and it’s often the single largest cost differentiator in an LSR mold quotation.

- Brand Reputation & Performance: World-class manufacturers like Fasto, Husky, or Yudo produce systems engineered specifically for LSR. They offer precise temperature control (critical for LSR’s fast cure time), minimal pressure drop, and reliable shut-off needle valves. This precision ensures consistent shot weight, reduces flash, and maximizes cycle time.

- The “Cost-Saving” Alternative: Lower-priced quotations often use generic or locally manufactured hot runners. These systems may suffer from temperature inconsistencies, leading to partially cured material, drooling, and a high scrap rate. The initial savings are quickly erased by lost material, production delays, and constant troubleshooting.

The Quotation Impact: A high-end hot runner system can easily double the cost of the mold base itself. However, for high-volume production, its ROI in efficiency and reliability is undeniable.

3. The Brain: Engineering & Design Expertise

LSR molding is fundamentally different from thermoplastic injection molding. The way the mold is designed—its “brain”—directly impacts its performance and cost.

- Cold Slug Wells & Gating: LSR begins to cure the moment it hits heat. Expert designers incorporate cold slug wells and optimal gate design to ensure the first material into the cavity is at the correct temperature, preventing uncured “snots” or rejects.

- Venting is Critical: Trapped air is a major issue with LSR due to its low viscosity. Superior mold designs feature extensive, well-placed venting (often using porous steel inserts) to allow air to escape completely. Poor venting results in burned parts, short shots, and inconsistent quality.

- Cooling Channel Design: Efficient cooling is vital for fast cycle times. Advanced factories use conformal cooling—channels that follow the contour of the part—which is more complex to manufacture but provides uniform cooling, reducing cycle times and warpage.

The Quotation Impact: You are not just paying for a CAD model; you are paying for years of specialized LSR experience that prevents costly errors and optimizes your production from day one.

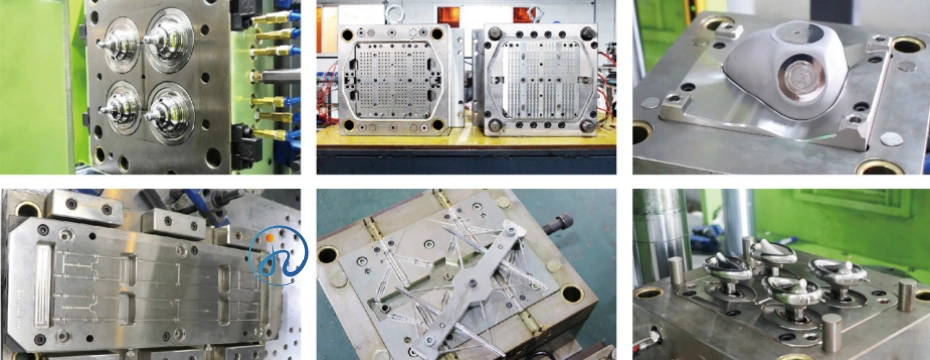

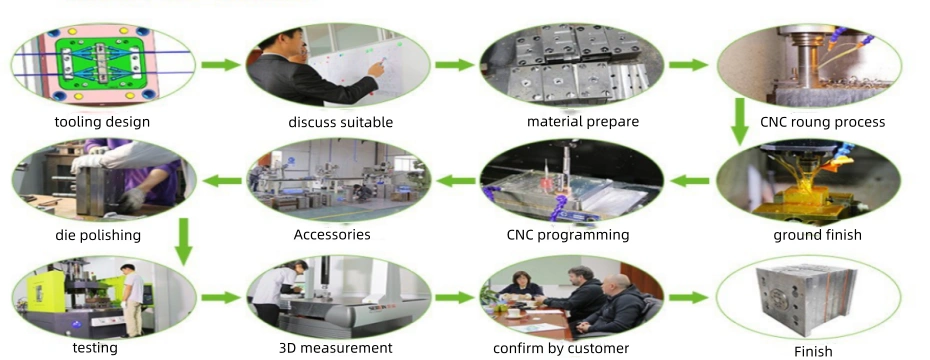

4. The Craftsmanship: Precision Machining & Finishing

A perfect design is worthless without the precision machinery and skill to execute it. This is where “shop rate” differences become apparent.

- Tolerances and Surface Finish: LSR parts often have tight tolerances and may require a mirror finish for medical or optical applications. Achieving this requires state-of-the-art 5-Axis CNC machines, EDM (Electrical Discharge Machining), and high-speed milling centers. The investment in this equipment is reflected in the quotation.

- The “Good Enough” Approach: A lower-cost factory may use older, less precise machinery. While the mold might look similar, imprecise machining leads to fit issues, flash along parting lines, and longer, more expensive try-out periods.

The Quotation Impact: High-precision machining takes more time and uses more expensive equipment, leading to a higher upfront cost but a mold that works flawlessly from the first shot.

5. The Hidden Factors: “Soft Costs” That Add Value

Finally, a comprehensive LSR mold quotation includes essential services that a cut-price competitor might omit.

- Project Management & DFM (Design for Manufacturability): A good factory will analyze your part design and suggest modifications to improve moldability, reduce cost, and enhance quality. This collaborative service is invaluable.

- Mold Flow Analysis (MFA): Advanced simulations predict how the LSR will fill the cavity, identifying potential air traps, weld lines, and cooling issues before steel is cut. This is a hallmark of a top-tier manufacturer.

- Comprehensive Support & Warranty: A reliable partner offers robust technical support, proper documentation, and a clear warranty. The cheapest quote often comes with the most limited support.

How to Evaluate an LSR Mold Quotation: A Practical Checklist

Don’t just look at the bottom line. Use this checklist to compare quotes intelligently:

- Ask for a Detailed Breakdown: What specific steel grade is listed? What brand and model of hot runner is quoted?

- Inquire About Design Process: Do they include Mold Flow Analysis? Can you review the DFM report?

- Request a Capabilities List & Case Studies: What kind of machinery do they use? Do they have experience with similar parts (especially medical or automotive)?

- Clarify the Scope: Does the price include sampling, inspection reports, and shipping? How many revisions are included?

- Assess Communication: A factory that asks insightful questions about your material, volume, and quality requirements during the quoting phase is likely more competent.

Conclusion: Price vs. Total Cost of Ownership

When you receive your next lsr mold quotation, remember that you are not just buying a piece of tooled steel. You are investing in the entire ecosystem that produces it: the materials, the engineering intellect, the precision machinery, and the long-term partnership.

The cheapest mold often has the highest total cost of ownership when you account for production downtime, high scrap rates, and frequent repairs.

The right mold, from a qualified and transparent partner, is a reliable production asset that ensures your LSR molding project is efficient, scalable, and profitable for years to come. Invest wisely.