Table of Contents

ToggleLiquid silicone kitchen products have become increasingly popular worldwide due to their food safety, heat resistance, flexibility, and durability. Products such as silicone spatulas, baking molds, oven gloves, ice trays, and cooking utensils are widely used in both household and professional kitchens.

For manufacturers and brands, understanding how to produce liquid silicone kitchen products is essential to ensure consistent quality, regulatory compliance, and cost-effective mass production.

This article provides a complete overview of the liquid silicone rubber (LSR) kitchen product manufacturing process, from raw material selection to final inspection.

What Are Liquid Silicone Kitchen Products?

Liquid silicone kitchen products are kitchenware items made from liquid silicone rubber (LSR) or food-grade silicone, designed for cooking, baking, food preparation, and storage.

Common Liquid Silicone Kitchen Products Include:

- Silicone spatulas and turners

- Baking molds and baking mats

- Silicone lids and food covers

- Ice cube trays

- Oven mitts and pot holders

- Silicone brushes

- Silicone bowls and containers

These products require high-purity, food-grade silicone to meet international safety standards.

Step 1: Product Design and Engineering

Understanding Kitchen Product Requirements

When designing liquid silicone kitchen products, manufacturers must consider:

- Heat resistance (up to 230–250°C)

- Non-stick performance

- Ergonomic design

- Easy cleaning and dishwasher safety

- Long-term durability

Design for Manufacturability (DFM)

Engineers use CAD software to optimize:

- Wall thickness consistency

- Draft angles for easy demolding

- Reinforcement ribs for strength

- Hanging holes or grip textures

Proper DFM reduces production defects and improves yield.

Step 2: Raw Material Selection (Food-Grade LSR)

What Is Liquid Silicone Rubber (LSR)?

LSR is a two-component, platinum-cured silicone elastomer known for its:

- Excellent thermal stability

- High purity and low volatility

- Odorless and tasteless nature

- Strong elasticity and tear resistance

Food-Grade Compliance

Only certified materials should be used:

- FDA 21 CFR 177.2600 (USA)

- LFGB (Germany)

- RoHS & REACH

Using substandard silicone can cause odor, discoloration, or safety issues.

Step 3: Mold Design for LSR Kitchen Products

LSR Injection Mold Characteristics

- High-precision cavities

- Cold runner system (no material waste)

- Mirror-polished surfaces

- Automated demolding capability

LSR molds are typically made from hardened steel to support high-volume production.

Mold Considerations for Kitchenware

- Multi-cavity design for efficiency

- Uniform heating for consistent curing

- Venting to eliminate air bubbles

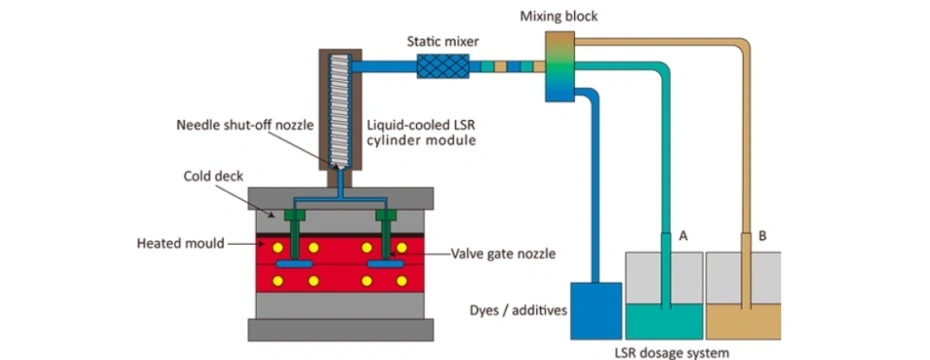

Step 4: Liquid Silicone Injection Molding Process

Standard LSR Kitchen Product Manufacturing Process

- Mixing LSR Part A and Part B

- Automatic metering and injection

- Mold heating and vulcanization

- Curing under controlled temperature

- Demolding of finished products

LSR injection molding offers high repeatability and minimal contamination, making it ideal for food-contact products.

Step 5: Secondary Processing and Assembly

Some liquid silicone kitchen products require additional steps:

- Plastic handle overmolding (PP or nylon)

- Logo engraving or laser marking

- Color matching and custom pigments

- Assembly of multi-component items

All secondary materials must also meet food-contact safety requirements.

Step 6: Post-Curing and Cleaning

Post-curing is essential for removing residual volatiles:

- Heat treatment in controlled ovens

- Washing with purified water

- Drying in clean environments

This process improves odor control and food safety performance.

Step 7: Quality Control and Inspection

Key Quality Checks

- Visual inspection for defects

- Dimensional accuracy measurement

- Hardness (Shore A) testing

- Tensile and tear strength testing

- Heat resistance testing

Compliance Testing

Third-party laboratory testing is recommended for:

- FDA food-contact approval

- LFGB migration testing

- BPA-free certification

Step 8: Packaging for Liquid Silicone Kitchen Products

Packaging Requirements

- Food-grade inner bags

- Dust-free sealing

- Clear labeling and instructions

- Barcode and traceability

Eco-friendly and recyclable packaging options are increasingly demanded.

Advantages of Liquid Silicone Kitchen Products

Compared with traditional plastic or rubber kitchenware, liquid silicone offers:

- Superior food safety

- Wider temperature tolerance

- Long service life

- Soft yet durable performance

These advantages explain the growing demand in global markets.

Market Trends in Silicone Kitchenware

- Minimalist and modern designs

- Custom branding for private labels

- Eco-friendly positioning

- Multi-functional kitchen tools

OEM and ODM manufacturers that adapt quickly gain competitive advantages.

Why Choose a Professional LSR Manufacturer?

Working with an experienced liquid silicone manufacturer ensures:

- Stable material sourcing

- Precision mold development

- Consistent mass production

- Reliable certification support

This is critical for brands entering the US and European kitchenware markets.

Conclusion

Understanding how to produce liquid silicone kitchen products is essential for delivering safe, durable, and high-quality kitchenware.

By using food-grade liquid silicone rubber, advanced injection molding technology, and strict quality control, manufacturers can meet international standards and growing market demand.

Partnering with a professional LSR manufacturer allows brands to bring innovative silicone kitchen products to market efficiently and confidently.