Table of Contents

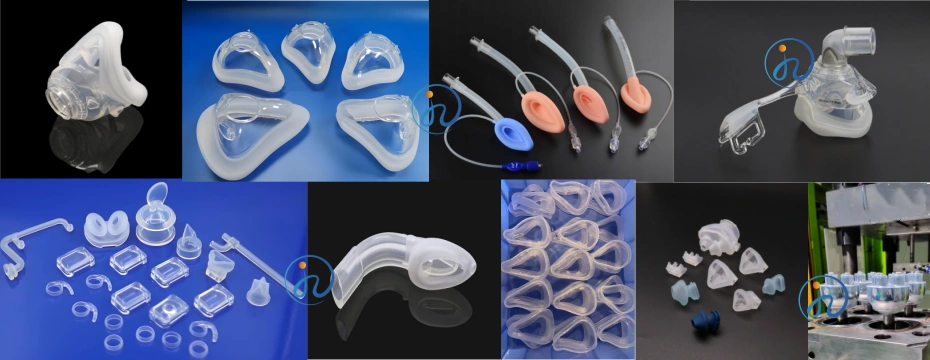

ToggleThe medical industry’s dependence on precision and customizability has led to the evolution of highly customized production processes, especially in the manufacture of injection-molded silicone parts. These components are vital for a wide range of medical devices, offering unparalleled performance thanks to their biocompatibility, durability, and versatility. This article delves into the intricacies of this process, shedding light on its significance, challenges, and technological advances that make it possible to meet the rigorous demands of medical applications.

Understanding the Process and Its Significance

The production of injection-molded silicone parts for medical applications is a sophisticated process that involves injecting heated silicone material into a precisely crafted mold. This method is favored for its ability to produce components with complex shapes and intricate details, which are often required in medical devices. The significance of this production method lies in its high repeatability and ability to create parts that meet the stringent quality standards of the medical industry, including biocompatibility, sterilizability, and resilience under various conditions.

Challenges in Customizing Medical Silicone Parts

Customization in the realm of injection-molded silicone medical parts is no small feat. Manufacturers face multiple challenges. Such as ensuring the precision of mold design, maintaining the integrity of silicone material throughout the production process, and meeting tight regulatory standards.

Technological Advances in Injection Molding

Technological advancements have played a pivotal role in overcoming the challenges associated with the highly customized production of silicone medical parts. Innovations such as computer-aided design (CAD) and computer-aided manufacturing (CAM) allow for precise mold design and manufacturing, ensuring the parts produced meet exact specifications. Additionally, the application of automation and robotics in the injection molding process has improved the efficiency and repeatability of production, crucial factors in meeting the demands of the medical industry.

Materials Science: The Heart of Customization

At the core of customizing injection-molded silicone parts for medical applications is materials science. The choice of silicone material can vastly influence the functionality and performance of the final product. There are different grades of medical silicone, each offering unique properties such as varying degrees of flexibility, tear resistance, and biocompatibility. Understanding these nuances allows manufacturers to tailor the material properties to the specific needs of the medical device, thereby optimizing its performance and safety for patients.

Looking Ahead: The Future of Customized Medical Silicone Parts

The future of highly customized production of injection-molded silicone medical parts looks promising, driven by continuous improvements in manufacturing technology, materials science, and design capabilities. The increasing demand for personalized medicine and the growth of minimally invasive surgeries are likely to further fuel the need for more sophisticated and customized silicone components. As the industry evolves, the ability to produce these parts efficiently and with high precision will remain a critical factor in the advancement of medical devices.

The production of highly customized injection-molded silicone medical parts stands as a pivotal component in the development and function of advanced medical devices. With ongoing technological progress and a deeper understanding of materials science, this field is set to meet the growing needs of personalized medicine and innovative medical treatments, pushing the boundaries of what is possible in healthcare technology and improving patient outcomes.