Table of Contents

ToggleCustom liquid silicone rubber (LSR) parts have gained immense popularity across industries such as medical, automotive, baby products, and electronics. Known for their flexibility, biocompatibility, heat resistance, and long-term durability, these parts are produced using a specialized process called LSR injection molding. However, businesses considering custom LSR components must understand the various cost factors that impact pricing. This article provides an in-depth look into the key cost components of manufacturing custom LSR parts and how they influence your overall project budget.

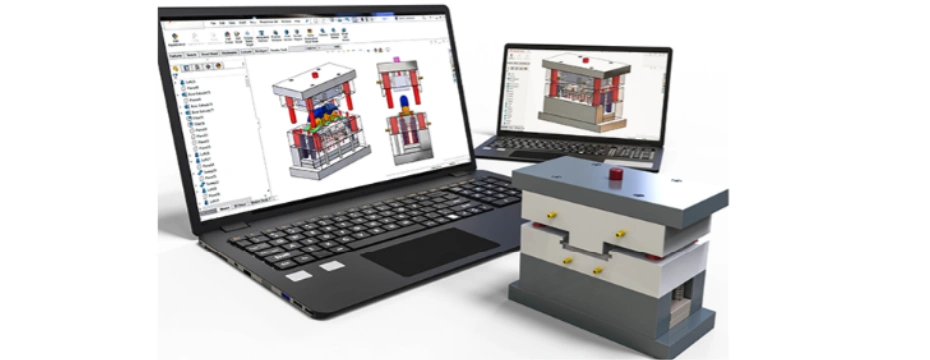

1. Tooling and Mold Manufacturing Cost

One of the most significant upfront investments in LSR injection molding is the tooling. Custom molds must be precisely machined to accommodate the properties of liquid silicone and the desired part geometry.

-

CNC Machined Mold Fabrication: High-precision CNC machining is required to produce durable steel or aluminum molds that can withstand the heat and pressure of LSR injection.

-

Multi-Cavity Molds: If large volumes are expected, multi-cavity molds are created to improve productivity, but they increase initial tooling costs.

-

Complexity and Part Design: Intricate features such as undercuts, micro channels, or overmolding requirements (e.g., LSR over PC or PPSU) will raise the mold development cost.

Estimated Cost Range: $3,000 – $50,000+ depending on complexity and cavities.

2. Material Cost: Liquid Silicone Rubber (LSR)

The base material for these parts—liquid silicone rubber—is a high-purity, two-part platinum-cured silicone. Its cost varies depending on the grade (medical, food, industrial) and additives used (colorants, flame retardants, etc.).

-

Medical-Grade LSR is the most expensive due to its biocompatibility certifications (e.g., USP Class VI).

-

Food-Grade LSR is slightly less costly but still tightly regulated.

-

General-Industrial LSR is more affordable for applications where strict compliance is not required.

Estimated Material Cost: $8 – $30 per kilogram.

3. Production Setup and Cycle Time

LSR injection molding requires a controlled environment and dedicated machinery. Although the material is self-leveling and ideal for automation, the setup still involves time and precision.

-

Injection Molding Machines: Specialized cold-runner LSR injection machines are required.

-

Cycle Time: LSR cures quickly but not instantly. Faster cure rates are possible with optimized tooling and temperature control.

-

Automation: While robotic demolding and material metering systems reduce labor, they increase the capital cost.

Typical Cycle Time: 15 – 90 seconds per part, depending on size and geometry.

4. Labor and Overhead Cost

Although LSR injection molding is highly automated, skilled technicians are still needed for:

-

Mold setup and changeovers

-

Process monitoring and quality control

-

Cleaning and maintenance

In addition, cleanroom environments are required for medical or baby care products, which increases utility, HVAC, and hygiene-related overhead.

Labor/Overhead Contribution: 10% – 25% of total manufacturing cost.

5. Quality Control and Testing Cost

Custom LSR parts, especially in critical applications, must meet stringent quality standards:

-

Dimensional inspections using 2D/3D measurement systems

-

Material testing for durometer, tensile strength, biocompatibility, etc.

-

Batch traceability and certification (FDA, ISO 13485, REACH, RoHS)

These quality steps are essential but add additional cost to each batch or production run.

6. Post-Processing and Secondary Operations

Depending on the application, LSR parts may require:

-

Deflashing (manual or cryogenic)

-

Laser marking

-

Bonding or assembly

-

Overmolding with plastic or metal inserts

Secondary operations extend the lead time and labor cost per unit but can add necessary function or branding.

7. Volume and Production Scale

Economies of scale play a vital role in custom LSR manufacturing. While small batch runs (under 1,000 pieces) may have high per-unit cost due to mold amortization and setup, larger orders benefit from:

-

Lower tooling cost per part

-

Improved machine utilization

-

Material purchasing in bulk

Unit Cost per Part Example:

-

Small volume (100 – 1,000 pcs): $3 – $10 per piece

-

Mid volume (5,000 – 10,000 pcs): $1 – $3 per piece

-

Mass production (50,000+ pcs): <$1 per piece (depending on design)

8. Shipping and Logistics Cost

Custom LSR parts often require protective packaging, temperature-controlled storage (for raw material), and careful handling during shipping. For global clients, air or sea freight adds additional cost and lead time.

-

Domestic logistics are simpler and less costly.

-

Export orders need additional paperwork, packaging, and compliance with international regulations.

Conclusion

The manufacturing cost of custom liquid silicone parts involves more than just raw materials. It’s a combination of LSR injection molding tooling, machine time, labor, quality control, secondary operations, and logistics. For companies looking to develop durable, high-performance silicone components, understanding these cost factors is essential for accurate project budgeting and product planning.

By partnering with an experienced LSR manufacturer, you can optimize design for manufacturability (DFM), reduce cycle times, and minimize waste—resulting in long-term savings and reliable production.

![]()

Need Help With Your Custom LSR Project?

At Jiaze, we specialize in LSR injection molding and custom silicone solutions tailored to your industry needs. Contact us today for a free consultation or quote.