Table of Contents

ToggleHeat Cured Rubber (HCR) is a superior silicone elastomer known for its linear molecular chains with exceptional molecular weight. This structure undergoes transformation either through organic peroxide catalysts or through platinum-driven mechanisms, resulting in unrivaled temperature and age-resistance.

![]()

Chemical Structure

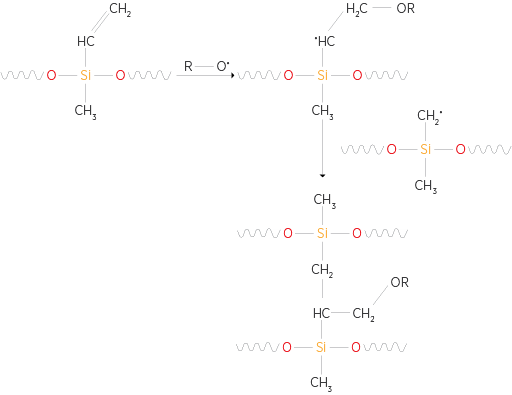

HCR elastomers, also termed as High Temperature Vulcanizing silicone rubber (HTV), derive from reactive silicone polymers. These straight chains have remarkable molecular weights and contain varied reactive entities. Predominantly used polymers include the partly phenylated or the perfluorinated vinylated variants. To enhance HCR’s inherent properties, components like fumed or precipitated silicas with an expansive surface area are introduced, alongside heat stabilizers and other specialized additives like plasticizers or anti-structuring agents. The curing or cross-linking of these elastomers is achievable via organic peroxides in polycondensation methods or platinum catalysts in polyaddition techniques.

Inherent Qualities of HCR Silicone

HCR elastomers stand out for their impressive attributes, setting them apart from traditional organic elastomers. These compounds showcase exceptional mechanical resilience across a wide temperature range, functioning effectively between -50 °C and +300 °C. Their longevity accentuates core features such as chemical neutrality, photostability, and the lack of lingering reactive components post-curing. These elastomers can be colored in various shades, and when combined with an appropriate silica filler, transparent items suitable for culinary and medical utilities can be crafted. With the incorporation of diverse additives, the potential applications of HCRs expand, offering solutions for myriad industries ranging from aerospace to electronics. One can find these elastomers playing pivotal roles in areas like heat management in Electric Vehicles or as conductive materials in power sectors.

HCR in the Automotive Realm

A prime example of HCR’s utility is seen in the automotive sector, especially electric vehicles. Given its inherent high and low-temperature resistance combined with its adaptability, automotive cable manufacturers are opting for HCR over polymers like TPU/TPE and XLPE. The evolving needs of the Electric Vehicle sector, particularly in connections between engines and batteries, are aptly met by HCR-crafted cables. These cables are not only heat resistant but also flaunt minimal smoke emissions, with their combustion gases being non-corrosive and non-toxic.

HCR At A Glance

- Technology: HCR

- Definition: Heat Cured Rubber, key components being (Gum+Silica+Plasticizer+Additives).

- General Traits: Exceptional thermal stability up to 300 ℃; Cold resilience up to -50 ℃, with specialized grades pushing these limits; Noteworthy electrical properties.

- Characteristic Properties:

- Hardness: 30~80 ShA

- Mechanical strength: 7~10 MPa

- Elongation: 200~800 %

- Tear strength: 15~40 N/mm

- Curing Mechanism

- Processing: Integration of color and catalysts using a 2-roll mill after kneader mixing.

- Applications: Predominantly in automotive parts like cables, gaskets, and hoses; Medical apparatuses like tubes and connectors; Electrical components such as insulators; Everyday utilities including kitchenware.

Why Use HCR Silicones?

HCR (Heat Cured Rubber) silicones have emerged as the material of choice in many applications, and for good reason. Firstly, their exceptional temperature resistance, spanning from as low as -50°C to highs of +300°C, ensures reliability under extreme conditions. This makes them indispensable in industries where temperature fluctuations are a norm. Furthermore, their outstanding aging resistance underlines their longevity and durability, often outlasting other materials. On a chemical level, HCRs are inert, providing unmatched resistance to various chemicals and environmental stressors. This chemical stability, combined with photo-oxidative resilience, ensures HCRs retain their properties even under continuous exposure to harsh conditions. Their adaptability allows them to be tailored for specific applications, be it in the aerospace, automotive, or healthcare sectors. When one factors in their potential for customization, from color variations to enhanced mechanical properties through additives, the versatility of HCR silicones becomes evident. In an evolving world with demanding industrial requirements, the benefits of using HCR silicones are clear, making them an invaluable asset across various sectors.

Related Applications of HCR Silicone

HCR’s unparalleled attributes have found their way into a myriad of industrial usages:

- Fluid Management and Sealing:

- Building Construction: HCR plays a crucial role in sealing solutions, particularly in joints, ensuring longevity and resilience.

- Aeronautical Applications: Given its ability to withstand varying temperatures, HCR is used extensively for sealing and piping needs in the aerospace industry.

- Automotive Sector: Vehicles benefit from HCR in various parts such as gaskets, protective boots, and hoses. Its durability and resistance make it an ideal choice.

- Electrical Safeguarding:

- Office Infrastructure: HCR finds its application in the safety cables of office devices, ensuring protection against electrical mishaps.

- Electrotechnical Components: Insulators crafted from HCR offer excellent resilience and longevity, particularly in high-demand electrical setups.

- Automotive Electronics: The significance of HCR is evident in spark plug boots, cables, and connectors. They not only offer protection but also ensure efficient energy transmission.

- Health and Wellness Applications:

- Culinary Uses: Owing to its inert nature and adaptability, HCR is utilized in kitchenware, ensuring food safety and durability.

- Pharmaceutical and Biomedical Sector: The medical world benefits from HCR in various capacities. From tubes to connectors and long-term implants, HCR ensures biocompatibility and durability.

By seamlessly integrating into these sectors, HCR silicone showcases its versatility, resilience, and unparalleled performance across diverse applications.

HCR vs. LSR: A Brief Overview

HCR (Heat Cured Rubber) and LSR (Liquid Silicone Rubber) are both forms of silicone rubber, but they differ significantly in their processing, properties, and applications. At a glance, HCR is a high-consistency rubber that requires heat to cure, often utilized in applications requiring robust mechanical properties. In contrast, LSR is a two-part, pourable liquid that cures rapidly under heat, making it ideal for intricate moldings and applications demanding precision.

While both forms of silicone offer excellent temperature resistance and flexibility, their distinct processing methods lead to different performance characteristics and, consequently, end-uses. For a more in-depth understanding of their differences, especially in terms of processing, we invite you to delve into our detailed article titled, “What are the different processing methods for silicone rubber?” This comprehensive guide will provide clarity on the unique attributes of each and their implications in the realm of silicone rubber applications.

Conclusion

Heat Cured Rubber (HCR) stands as a testament to the advancements in silicone elastomer technology. Its unique chemical structure, crafted from reactive silicone polymers, ensures unmatched resilience across extreme temperature ranges. Beyond its inherent attributes like photostability and chemical neutrality, HCR’s adaptability allows it to cater to a plethora of industries. From the automotive and aerospace sectors to the realms of electrical safety and healthcare, HCR has carved a niche for itself. Its extensive use in sealing, electrical protection, and health-related applications underscores its unparalleled significance in modern industrial applications. As we continue to push the boundaries of technological innovation, HCR’s role becomes ever more pivotal, making it a cornerstone material for the future.