Table of Contents

ToggleAutomotive liquid injection molding applications refer to the use of Liquid Silicone Rubber (LSR) injection molding technology to manufacture high-performance silicone components for the automotive industry. With the rapid development of electric vehicles, intelligent driving systems, and stricter safety and environmental regulations, automotive manufacturers increasingly rely on LSR liquid injection molding to produce durable, precise, and reliable parts.

Liquid injection molding enables the mass production of complex automotive silicone components with excellent heat resistance, chemical stability, flexibility, and long service life, making it an essential manufacturing process in modern vehicles.

1. What Is Automotive Liquid Injection Molding?

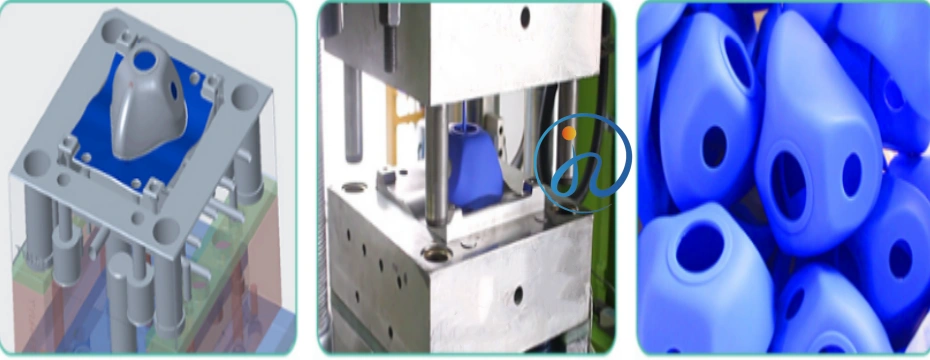

Automotive liquid injection molding is a manufacturing process that injects two-part liquid silicone rubber (LSR) into a heated mold to produce precision silicone components for vehicles. The process is fully automated and suitable for high-volume automotive production, ensuring consistent quality and tight tolerances.

Unlike traditional rubber compression or transfer molding, liquid injection molding allows:

- Shorter cycle times

- Flash-free molding

- Complex geometries

- Integrated sealing and functional designs

This makes it ideal for automotive parts requiring high reliability and repeatability.

2. Why Liquid Silicone Rubber Is Used in Automotive Applications

The automotive industry demands materials that can withstand extreme conditions such as:

- High temperatures

- Continuous vibration

- Exposure to oils, fuels, and chemicals

- UV radiation and weathering

Liquid Silicone Rubber meets these demands better than many conventional elastomers.

Key reasons automotive manufacturers choose LSR include:

- Excellent thermal resistance

- Long-term durability

- Electrical insulation properties

- Environmental compliance (RoHS, REACH)

- Compatibility with automated production lines

3. Key Properties of LSR for Automotive Industry

Liquid Silicone Rubber offers a unique combination of properties essential for automotive use:

High Temperature Resistance

LSR maintains stable performance from -40°C to +200°C, making it suitable for both interior and engine compartment applications.

Chemical and Oil Resistance

Automotive LSR components resist:

- Engine oil

- Coolants

- Transmission fluids

- Fuels and cleaning agents

Flexibility and Elastic Recovery

LSR parts retain elasticity even after long-term compression, ideal for seals and gaskets.

Weather and UV Resistance

LSR does not crack, harden, or yellow under prolonged UV exposure, making it perfect for exterior automotive parts.

4. Major Automotive Liquid Injection Molding Applications

Automotive liquid injection molding applications cover nearly every area of a modern vehicle, including:

- Interior components

- Exterior sealing systems

- Powertrain and under-the-hood parts

- Automotive electronics and sensors

- Electric vehicle (EV) systems

These applications continue to expand as vehicle designs become more complex.

5. Interior Automotive LSR Components

LSR injection molding is widely used for interior automotive parts due to its softness, durability, and low VOC emissions.

Common interior applications include:

- HVAC sealing gaskets

- Air vent membranes

- Button covers and keypads

- Control panel seals

- Noise and vibration damping components

LSR materials can be customized to meet automotive interior standards for odor, fogging, and touch comfort.

6. Exterior Automotive LSR Components

For exterior vehicle parts, liquid silicone rubber provides superior resistance to environmental stress.

Typical exterior automotive LSR applications:

- Door and window sealing systems

- Lighting seals for headlights and taillights

- Sunroof seals

- Camera and sensor protection covers

Thanks to its UV and ozone resistance, LSR ensures long-term performance without degradation.

7. Under-the-Hood LSR Applications

Under-the-hood environments require materials that can survive extreme heat and chemical exposure.

Liquid injection molded LSR parts used under the hood include:

- Engine sealing gaskets

- Turbocharger seals

- Spark plug seals

- Hose connectors

- Thermal insulation components

LSR maintains flexibility and sealing performance even after prolonged exposure to heat and vibration.

8. Automotive Electronics & Sensor Applications

As vehicles become more intelligent and electrified, automotive electronics require reliable protection and insulation.

LSR injection molding is commonly used for:

- Sensor housings and seals

- ADAS camera protection

- Battery pack sealing

- Connector seals

- Electric motor insulation components

Liquid silicone rubber provides excellent electrical insulation and moisture protection, critical for electronic safety and performance.

9. Automotive Liquid Injection Molding Process

The automotive liquid injection molding process is designed for high efficiency and consistency.

Step 1: Material Metering & Mixing

Two liquid silicone components are precisely metered and mixed to ensure uniform curing.

Step 2: Injection into Heated Mold

The LSR is injected into a steel mold heated to 150–200°C, where it flows easily into complex cavities.

Step 3: Vulcanization

The silicone cures rapidly inside the mold, forming a durable elastomer.

Step 4: Automated Demolding

Parts are automatically removed, minimizing contamination and ensuring consistent quality.

10. Design Considerations for Automotive LSR Parts

Proper design is critical for successful automotive liquid injection molding applications.

Key design factors include:

- Uniform wall thickness

- Proper gate location

- Venting to avoid air traps

- Mold surface finish

- Integration with plastic or metal components (overmolding)

Early collaboration with an experienced LSR manufacturer helps reduce tooling costs and development time.

11. Advantages of LSR Injection Molding for Automotive Manufacturing

Compared with traditional rubber processing methods, liquid injection molding offers:

- High precision and repeatability

- Reduced material waste

- Short cycle times

- Automation compatibility

- Lower long-term production costs

These advantages make LSR injection molding ideal for automotive mass production.

12. Future Trends of Liquid Injection Molding in Automotive Industry

The demand for automotive liquid injection molding applications continues to grow due to:

- Electric vehicle expansion

- Lightweight vehicle design

- Increased use of sensors and electronics

- Stricter environmental regulations

In the future, LSR will play an even greater role in battery systems, autonomous driving components, and integrated sealing solutions.

13. Conclusion

Automotive liquid injection molding applications are essential to modern vehicle manufacturing. With its outstanding thermal stability, durability, and design flexibility, Liquid Silicone Rubber injection molding enables the production of high-quality automotive components that meet the industry’s strict performance standards.

As automotive technology evolves, liquid injection molding will continue to support innovation, safety, and efficiency across the entire vehicle platform.