Table of Contents

ToggleIn modern manufacturing, combining multiple materials through overmolding has become an essential process to achieve superior product performance. One of the most advanced techniques today is PPSU overmolding LSR. This process integrates polyphenylsulfone (PPSU), a high-performance thermoplastic, with liquid silicone rubber (LSR), a versatile elastomer, into a single component.

The result is a product that combines strength, heat resistance, and toughness from PPSU with the flexibility, softness, and biocompatibility of LSR. This makes it a preferred choice in industries such as medical devices, baby products, food contact components, and precision engineering.

In this article, we’ll explore what PPSU overmolding LSR means, the step-by-step process, benefits, applications, and design considerations for engineers and buyers.

1. Understanding PPSU Material

Before diving into the overmolding process, it’s important to understand the base materials.

- What is PPSU?

PPSU (polyphenylsulfone) is a high-performance thermoplastic known for its:- High heat resistance (up to 207°C continuous use temperature)

- Excellent hydrolysis resistance

- Toughness and impact strength

- Superior chemical resistance

- Long life in repeated sterilization cycles (autoclave resistance)

PPSU is widely used in:

- Medical instruments (surgical trays, sterilization cases)

- Baby feeding bottles (due to safety and durability)

- Aerospace and automotive parts requiring high toughness

2. Understanding LSR (Liquid Silicone Rubber)

Liquid Silicone Rubber (LSR) is a two-part platinum-cured silicone material that can be injection molded. It is widely used due to its:

- Softness and flexibility

- Biocompatibility (safe for skin and body contact)

- Thermal stability (resistant to high and low temperatures)

- Transparency and coloring options

- Long-term durability

Common applications include:

- Medical devices (seals, valves, masks, catheters)

- Baby products (nipples, pacifiers, bottle parts)

- Electronics (keypads, connectors)

3. What is PPSU Overmolding LSR?

PPSU overmolding LSR refers to the process where LSR is injection-molded over a pre-formed PPSU substrate.

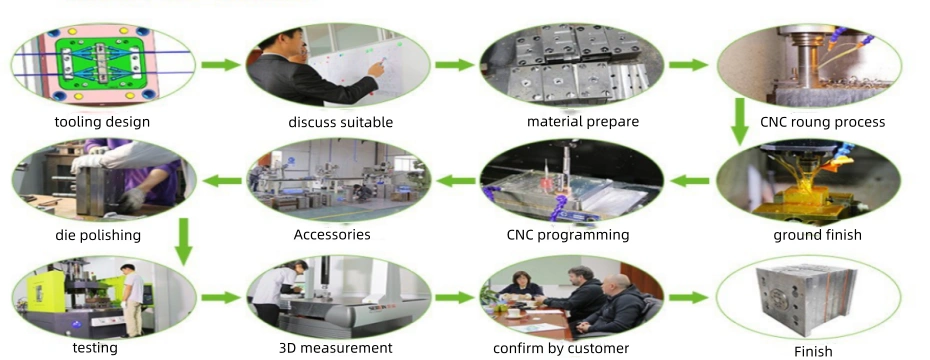

- Step 1: The PPSU component is manufactured through injection molding.

- Step 2: The PPSU part is placed into a mold cavity designed for overmolding.

- Step 3: Liquid silicone rubber is injected onto the PPSU surface under high pressure.

- Step 4: LSR chemically and mechanically bonds to PPSU, creating a single integrated component.

This combination allows manufacturers to produce parts that leverage PPSU’s rigidity and strength with LSR’s softness, sealing, and comfort.

4. Advantages of PPSU Overmolding LSR

The PPSU overmolding LSR process offers unique benefits that make it stand out among material combinations:

4.1 Strong Bonding

- The process creates permanent chemical and mechanical adhesion between PPSU and LSR.

- No need for adhesives, which improves safety for medical and food applications.

4.2 Design Flexibility

- Engineers can combine rigid and soft areas in a single product.

- Allows complex geometries, ergonomic designs, and multifunctional parts.

4.3 Safety and Biocompatibility

- Both PPSU and LSR are FDA-approved and BPA-free, making them suitable for medical devices and baby care products.

4.4 Durability and Performance

- PPSU provides impact and heat resistance, while LSR adds sealing and comfort.

- Excellent performance in sterilization environments (autoclave, boiling, chemical cleaning).

4.5 Cost Efficiency

- Reduces assembly steps since two materials are combining in one process.

- Eliminates the need for secondary bonding processes.

5. Applications of PPSU Overmolding LSR

The process is increasingly popular in industries that require safety, durability, and multifunctionality:

5.1 Medical Industry

- Surgical instrument handles (rigid PPSU base + soft LSR grip)

- Respiratory masks (rigid PPSU structure + soft LSR sealing edge)

- IV connectors, seals, and valves

5.2 Baby Care Products

- Baby feeding bottles (PPSU body + LSR nipple or anti-colic valve)

- Pacifiers with dual-material comfort

- Soft handles and anti-slip grips

5.3 Food Contact Products

- Kitchenware with rigid PPSU cores and soft silicone handles

- High-heat cooking tools

5.4 Industrial and Electronics

- Keypads and housings

- Sealed connectors requiring rigid/soft integration

6. Technical Considerations for PPSU Overmolding LSR

For engineers and buyers, it’s crucial to consider the following technical points:

- Surface Preparation

- PPSU must be precisely molded and prepared for strong bonding with LSR.

- Mold Design

- Requires specialized tooling to ensure proper flow and bonding of LSR.

- Processing Temperature

- PPSU requires high molding temperatures; molds must handle LSR curing without degrading PPSU.

- Shrinkage and Tolerance

- Engineers must account for shrinkage differences between PPSU and LSR to ensure perfect fit.

- Material Compatibility

- Not all grades of PPSU and LSR bond equally well; material selection is critical.

7. Why Choose PPSU Overmolding LSR?

For manufacturers and product designers, the decision to use PPSU overmolding LSR often comes down to three factors:

- Performance: Enhanced product strength, comfort, and usability.

- Safety: Non-toxic, BPA-free, FDA and ISO medical-grade compliance.

- Efficiency: Reduced assembly steps, lower costs, and better product durability.

8. Future Outlook

With increasing demand for safe, durable, and multifunctional products in healthcare, baby care, and industrial sectors, PPSU overmolding LSR is expecting to expand rapidly. Advances in material science and processing technologies will continue to improve bonding strength, shorten cycle times, and reduce costs.

This process is not only a manufacturing innovation but also a strategic choice for high-value industries aiming for long-lasting, user-friendly, and regulatory-compliant products.

Conclusion

The PPSU overmolding LSR process represents the best of both worlds: the toughness of PPSU combined with the comfort and safety of LSR. It is an ideal solution for medical devices, baby products, food contact parts, and advanced industrial components.

By understanding the materials, process steps, advantages, and applications, engineers and buyers can make informed decisions when selecting this advanced manufacturing method.